INDUSTRIAL PLASTIC GRANULATOR SOLUTIONS

Convert waste into profit with our advanced recycling technology. Designed for performance, built for sustainability.

REQUEST A QUOTEAPPLICATIONS

Our industrial granulators are designed to process a wide range of materials with maximum efficiency and minimal maintenance.

Agriculture | BOPP Film

Recycle BOPP film waste, reduce plastic pollution, and recover valuable raw materials.

Waste Textile

Recycle waste textile to reduce the burden on landfills and recover fibers for reuse.

Waste Belts

Process waste belts safely, prevent hazards, and enable rubber/energy recovery.

Plastic Profiles

Recycle valuable PVC from profile waste, reduce material use and waste risks.

Rigid Plastics

Recover valuable ABS, HDPE, and PC from rigid plastic waste for a circular economy.

Plastic Bottles

Recycle PET bottles to combat plastic pollution and save raw materials.

Electronic Waste

Process e-waste plastics safely, prevent pollution, and recover materials.

Visnetten

Combat Ocean Pollution: Recycle Valuable Polymers (PA/PE) from Discarded Fishing Nets.

Bigbags | FIBC’s

Recycle Large Woven Bigbags (FIBC’s), Save Storage Space & Recycle PP.

Plastic Extrusion Blocks

Recycle Valuable Plastic by Granulating Large Extrusion Blocks and Cleaning Material.

OUR MACHINES

Precision Designed, Built for Sustainability: Our industrial granulators deliver unparalleled performance in plastic recycling.

PVC Grinding System

Advanced temperature-controlled grinding technology that maintains material integrity during the processing of hard PVC components on an industrial scale.

Micronization

Precision technology for ultrafine particle reduction with adjustable output size of 0.5-2 mm, enabling high-quality powder applications.

Plastic Granulator

Industrial granulator systems with hardened steel rotors and adjustable sieve configurations for optimal throughput and energy efficiency.

Pipe & Profile Breaker

Heavy-duty breaker systems specially designed for large diameter pipes and structural profiles with minimal risk of jamming and consistent output.

Single-Axis Shredder

Robust primary reduction equipment with high-torque drive systems and replaceable cutting inserts for processing large volumes of waste streams.

Horizontal Pipe Shredder

Innovative feed system design for continuous processing of long pipe sections with minimal operator intervention and maximum throughput.

OUR TECHNOLOGY

Innovative technical solutions that maximize material recovery while minimizing operational costs.

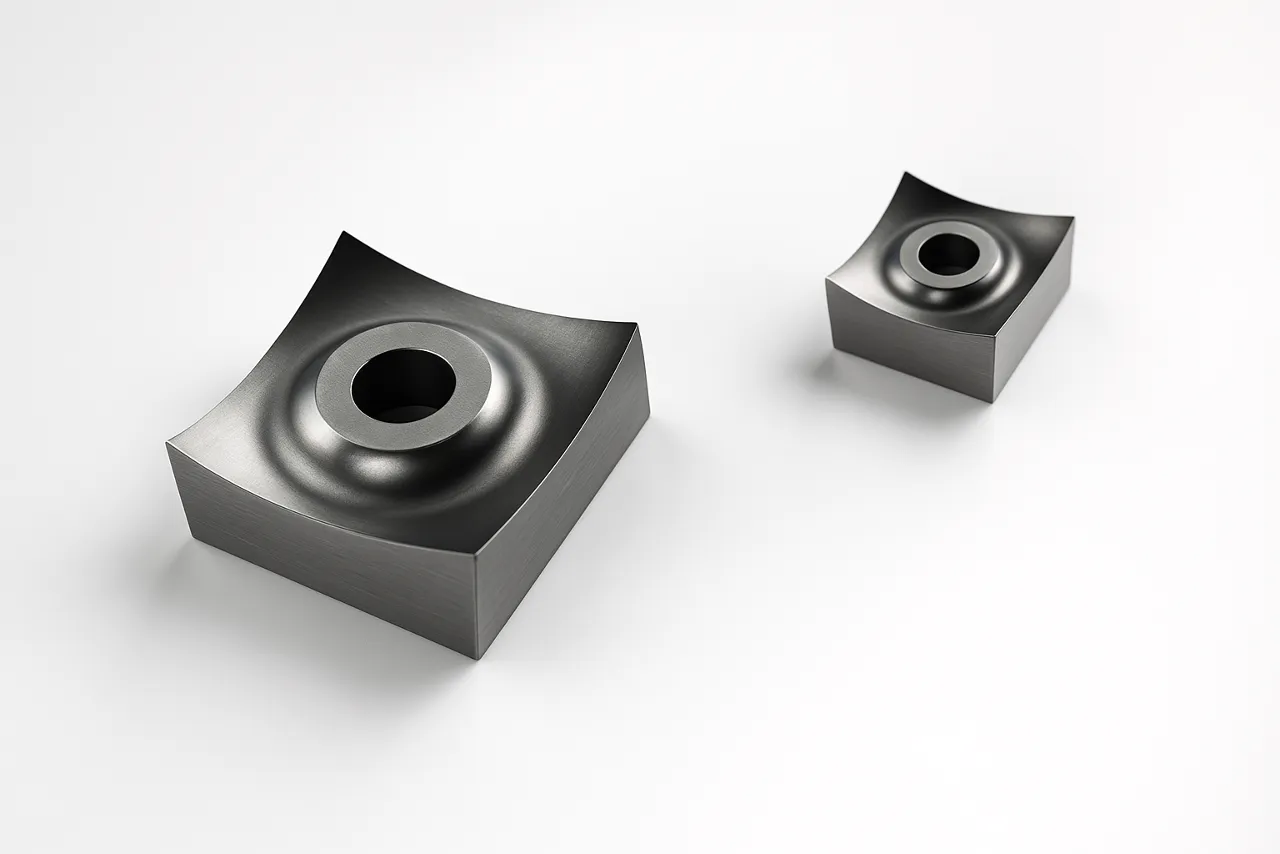

Precision Cutting Technology

Our patented rotor design combines optimal cutting angles with hardened tool steel blades for maximum durability and consistent performance, even with abrasive materials.

The specially developed shear cutting principle minimizes heat generation and reduces energy consumption, while maintaining a high throughput capacity for various material streams.

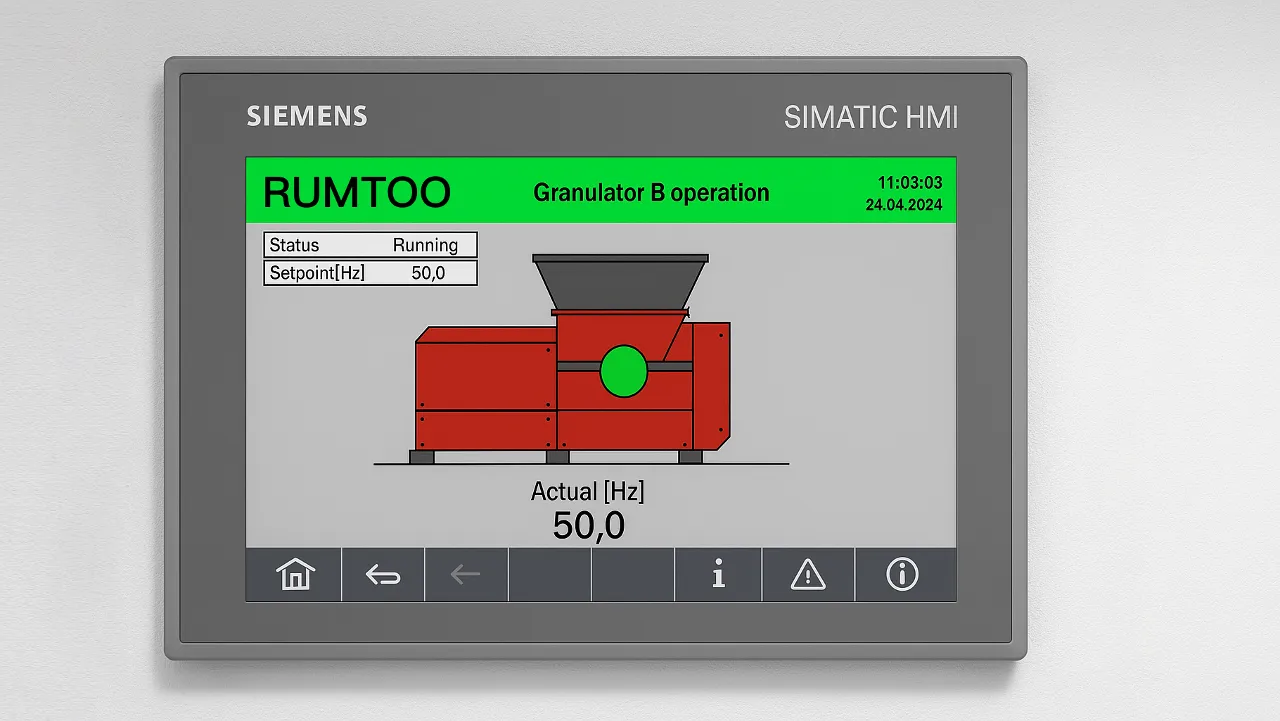

Smart Control Systems

Our industrial granulators are equipped with advanced PLC control systems with real-time monitoring and automatic overload detection to maximize efficiency and prevent damage from overloading or contamination.

Remote Diagnostic Capabilities make proactive maintenance planning and quick problem-solving possible, thereby minimizing costly downtime in production environments.

Energy Optimization

Our systems incorporate Siemens variable frequency drives that adjust energy consumption based on material throughput, thereby reducing energy costs while maintaining optimal processing parameters.

Innovative flywheel designs and kinetic energy recovery systems maximize efficiency, even when processing tough materials, resulting in significantly lower operational costs.

FREQUENTLY ASKED QUESTIONS

Find answers to your questions here. Can't find the answer you're looking for? Please contact us.

What materials can your granulators process?

Our granulators are highly versatile and can process a wide range of plastics, including hard plastics (HDPE, PVC, ABS), soft plastics (LDPE film, PP bigbags), profiles, pipes, and even more complex materials such as textiles and e-waste. For specific or contaminated material streams, we recommend contacting us for an analysis and possibly a material test.

What is the difference between a shredder and a granulator?

A shredder is generally used for primary, coarse reduction of large and bulky materials (e.g., whole bales of plastic, car tires). A granulator is used for secondary, finer reduction to produce a uniform, small granulate that can be reused or further processed. They are often used together in a recycling line: first the shredder, then the granulator.

How do I choose the right machine for my application?

The choice depends on several factors: the type of material, the size and shape of the input material, the desired output size (granulate size), and the required capacity (kg/hour). Our team of experts would be happy to assist you in selecting the perfect machine. Please contact us for a free consultation.

What is the situation regarding maintenance and spare parts?

Our machines are designed for durability and minimal maintenance. Wear parts such as blades and screens are easy to replace. We offer a full range of original spare parts and can provide service and maintenance plans to maximize the lifespan and performance of your equipment.

Do you offer the possibility to test our materials?

Absolutely. We understand that each material stream is unique. We encourage customers to send material samples for a test run in our test center. This way, you can see the performance of our machines with your own eyes and be assured of the right solution for your specific application.

Ready to optimize your recycling process?

Request a Consultation.

Read more about Textile Waste Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics