A swing arm shredder uses a hydraulic swing arm armature to keep bulky and dirty feed in motion towards the rotor. This guide covers the operating principle, important components, RDF SRF applications, and WT model selection based on feed size and target output.

Category Archives: news

Discarded fishing nets – often referred to as ghost nets – primarily consist of nylon (PA) and polyolefins (PP/PE). These materials are technically recyclable, provided they are processed correctly. This guide is written from the perspective of buyers and operators and focuses on how and why specialized shredders are needed, which configurations are practical [...]

The recycling of carpet and furniture fabric waste poses a significant challenge within the circular economy. These materials often consist of multiple layers, strong fibers, and various plastics, which can cause conventional machines to quickly jam or underperform. An industrial textile shredder, specifically designed for heavy and bulky textile waste, is therefore essential for efficient and reliable processing. Why [...]

When investing in textile recycling equipment, understanding the factors that influence the price of a textile shredder is crucial for an informed decision. This guide helps you navigate the pricing landscape and determine the best value for your specific needs. What affects the price of a textile shredder? Machine Capacity and Throughput The processing capacity of the machine is a key factor in determining the price.

Introduction Many businesses and consumers wonder: “Can you shred fabric in a shredder?” Rumtoo explains in this article when it is possible to shred fabric, which machines are suitable, and what safety and recycling tips you should follow. This article is intended for facility managers, textile producers, recycling companies, and sustainable entrepreneurs who want to process textile waste.

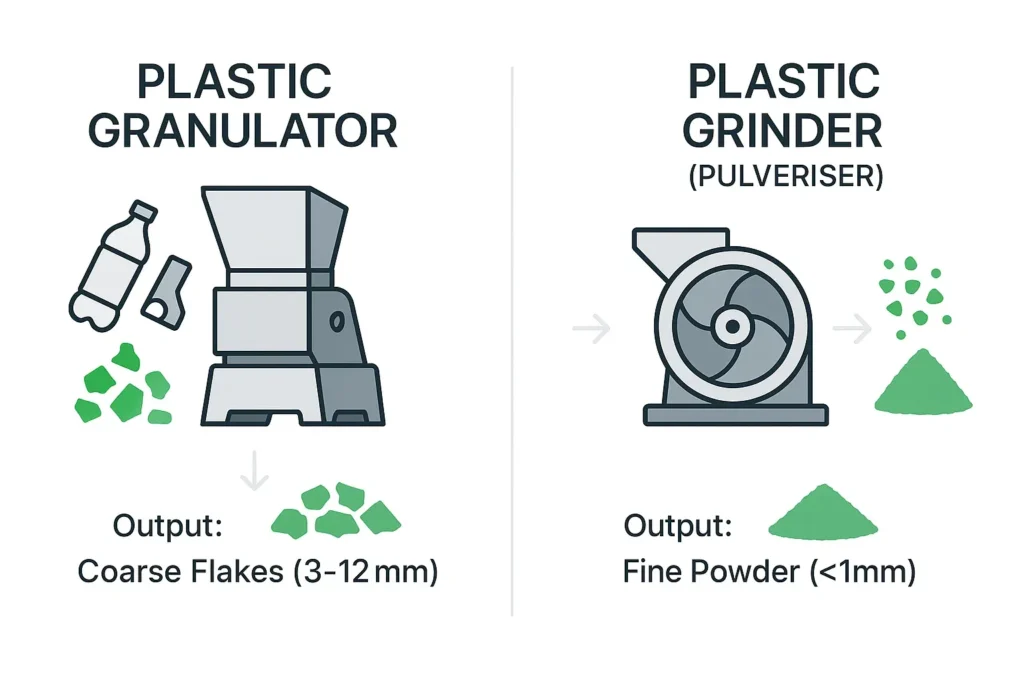

Choosing a Plastic Granulator for Regrind or a Grinder (Pulverizer) for Fine Powder? This guide outlines the crucial differences in operation, output, and application, so you can select the most efficient machine for your process and avoid costly mistakes.

The Heart of Plastic Recycling: The PET Washing Line A PET bottle recycling washing line is a complete, advanced production line designed for one crucial goal: converting bales of used PET bottles into extremely clean, high-quality PET flakes. These flakes are the direct raw material for new, sustainable products and are essential for a functioning circular economy. Why is Specialized Cleaning Necessary?.

How to Choose the Best Single Shaft Shredder for Plastic Recycling The power of the right shredder lies in its ability to be the motor of your plastic recycling. It is the machine that converts large, bulky waste into a valuable, reusable raw material. But how do you find the perfect match for your company? This guide will help you get started. Why Choose a Single Shaft Shredder? If you are serious about recycling, a single shaft shredder is a crucial investment.

news

Cost of Plastic Recycling Machines: Complete Investment Guide for 2025 Author: This article is compiled by the technical team of Rumtoo Machine, with over 15 years of experience in the development and implementation of plastic recycling solutions for industrial customers worldwide. The information is based on current market data, technical specifications, and practical experience from hundreds of project installations. Investing in a plastic recycling machine represents a crucial decision for your business.

From Waste to Value: The Power of Innovative Solutions for Textile and Dust Shredding

Auteur: Dit artikel is samengesteld door het technische team van Rumtoo Machine, met meer dan 15 jaar ervaring in de ontwikkeling en implementatie van kunststof recyclingoplossingen voor industriële klanten wereldwijd. De informatie is gebaseerd op actuele marktgegevens, technische specificaties en praktijkervaringen uit honderden projectinstallaties. De investering in een plastic recycling machine vertegenwoordigt een cruciale beslissing […]

Discover how Rumtoo's advanced textile shredders convert textile waste into valuable raw materials. Reduce costs, minimize your environmental impact, and strengthen the circular economy.

Discover the crucial benefits of industrial plastic granulators for waste recycling. Reduce costs, increase efficiency, and promote sustainability with Rumtoo Machine's solutions.

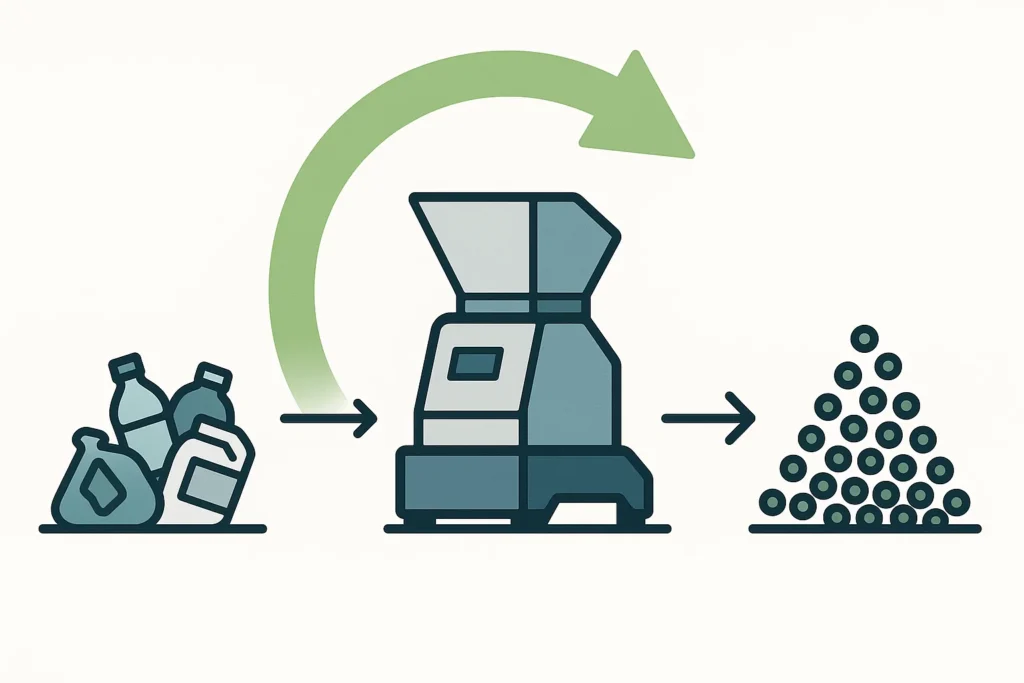

A plastic PET granulator is an essential machine for efficiently recycling PET waste such as bottles and packaging. This machine reduces waste to uniform granulate (raw material), which serves as a feedstock for new products. This guide covers the operation, the main benefits such as cost savings and sustainability, and the critical features professionals should consider when purchasing, such as knife quality and the option for wet granulation.

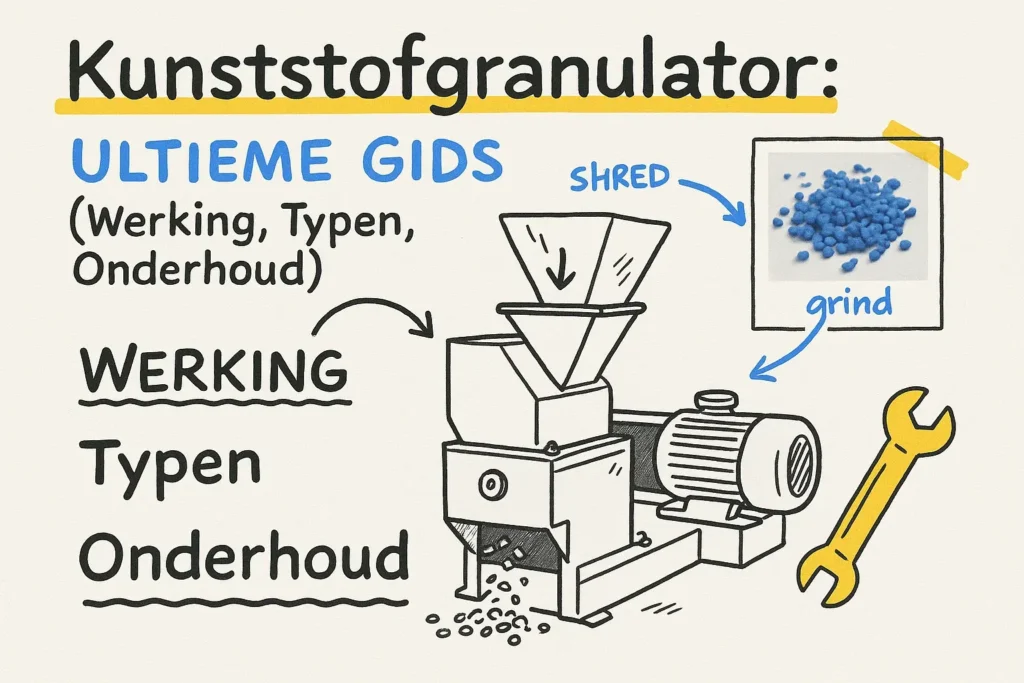

Learn everything about plastic granulators: operation, applications, maintenance, and benefits. The perfect guide for sustainable and efficient plastic processing.

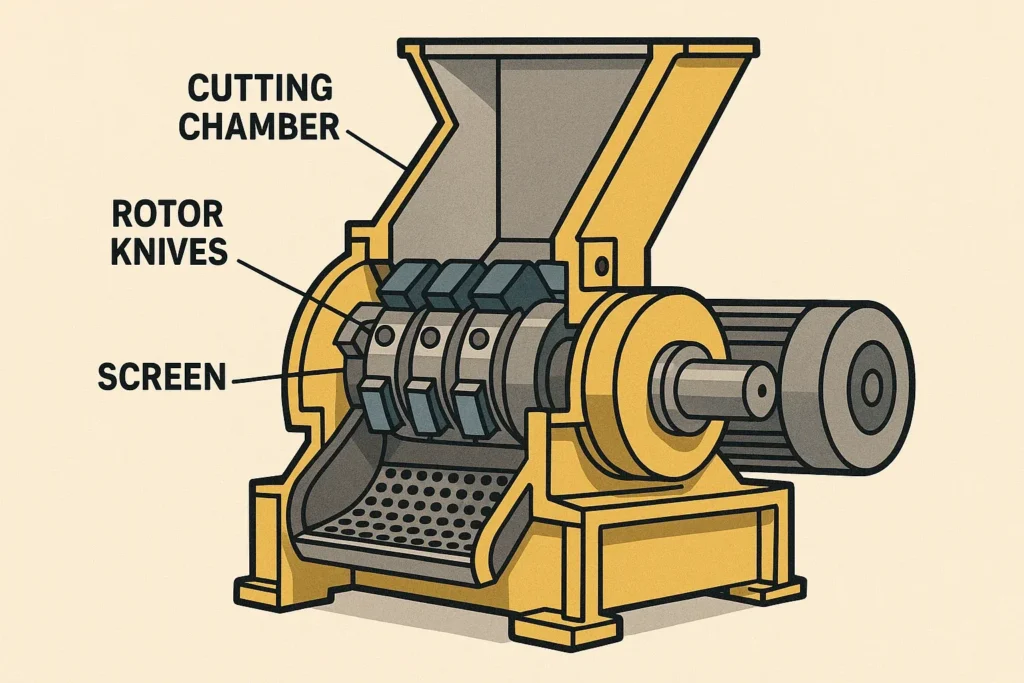

Immerse yourself in the world of plastic granulators. Discover how they work, the various types (cutting, V-type, helical), what affects their speed, the benefits of wet granulation, and best practices for use and maintenance. Essential knowledge for effective plastic recycling.

Choosing the Right Screen Size for Your Plastic Granulator Selecting the correct screen size for the sieve of your plastic granulator is essential for optimizing granulation processes, ensuring efficiency, and maximizing output quality. This comprehensive guide is specifically designed for industrial equipment buyers, engineers, and technical staff, and provides clear, direct guidance on this topic.

Granulators vs. Shredders vs. Pelletizers: Understanding the Differences and Synergies In the world of plastic recycling, granulators, shredders, and pelletizers are three common, yet functionally different devices. A clear understanding of their differences and interrelations is crucial for optimizing recycling processes. Shredder A shredder is primarily used for the initial reduction of large, bulky materials into smaller pieces [...]

Safety First: A Clear Explanation of EU CE & US OSHA Compliance for Industrial Plastic Shredders Industrial plastic shredders are powerhouses in recycling and waste management, efficiently reducing large volumes of plastic waste to manageable sizes. However, their power also brings inherent risks. Ensuring the safety of these machines requires navigating complex regulatory landscapes, primarily involving EU CE and US OSHA compliance.

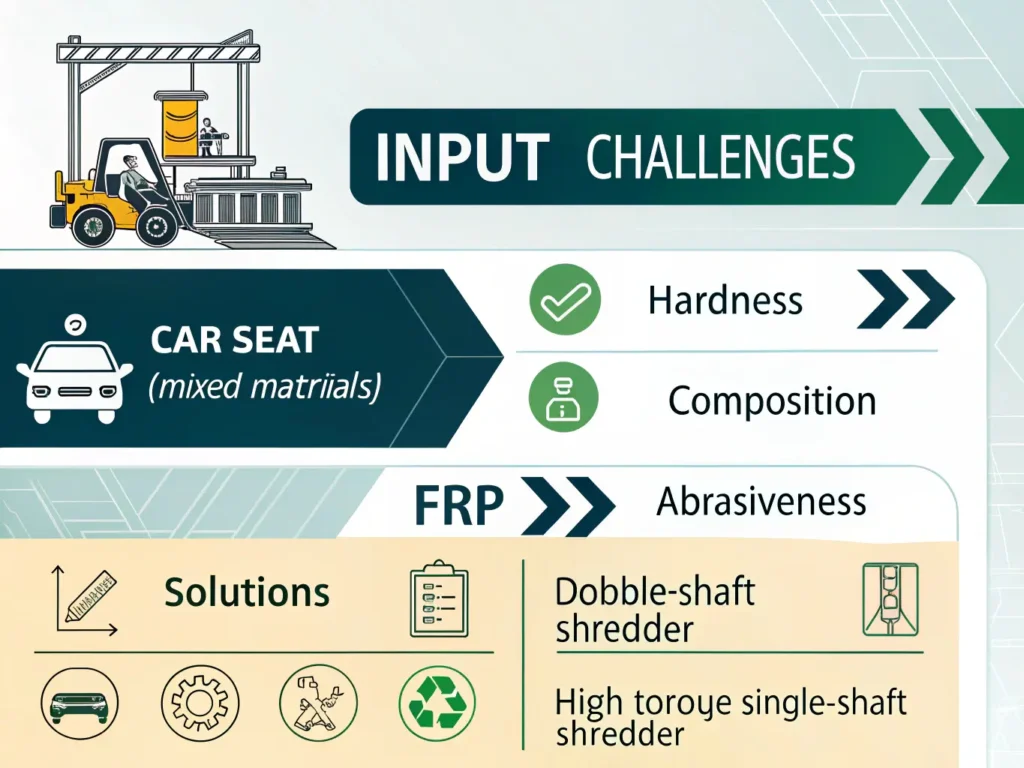

In the world of industrial shredding, processing difficult materials such as complex car seats, fiber-reinforced plastics (FRPs), or other challenging materials requires specialized machines designed to handle tough textures, densities, and structures. Whether it's shredding intricate car seats, FRPs, or other difficult materials, the right equipment is crucial for efficiency and quality.

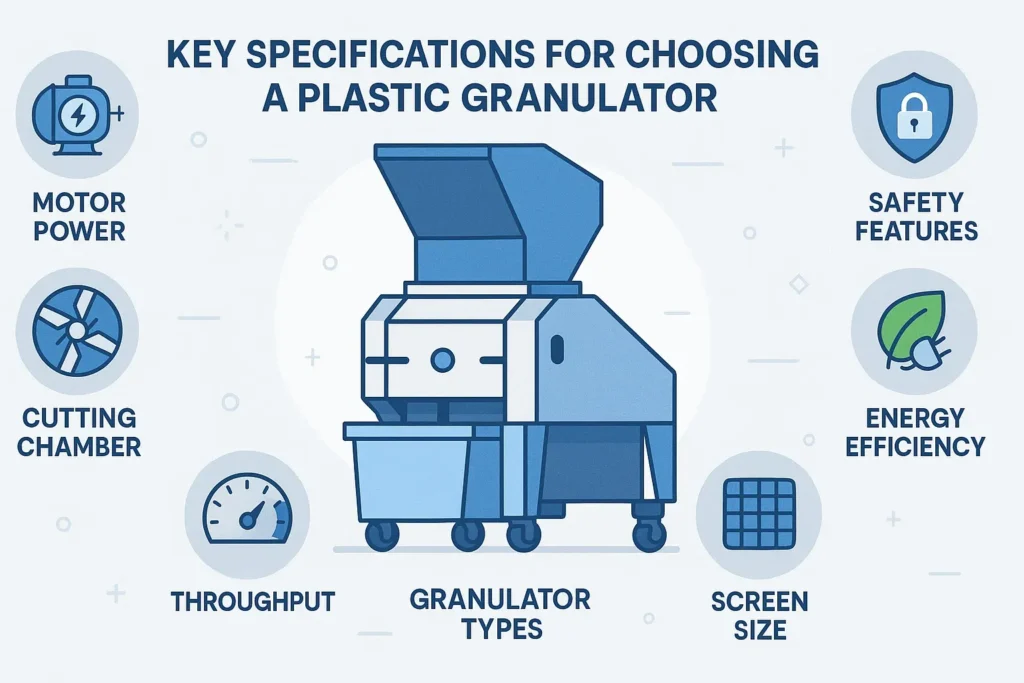

Consider purchasing a new plastic granulator (also known as a mill or grinder) for your business? Whether you aim to enhance your recycling efforts or streamline your material processing, it is absolutely crucial to get the technical details right. For industrial applications, the following specifications are essential to consider [...]

Regular maintenance of your plastic granulator is crucial. Learn how to prevent costly damages by taking preventive care of blades, screens, and safety procedures, extending the lifespan, and maximizing ROI.

Dealing with granulator clogs or excessive noise? This comprehensive guide offers practical solutions and maintenance tips for technical staff and engineers to maximize efficiency and minimize downtime.

With the increasing demand for recycled plastics, the need for efficient and reliable processing solutions is becoming increasingly crucial. At the heart of this process is the plastic granulator – an essential machine that converts plastic waste into reusable materials. Whether you want to improve your recycling efficiency or produce high-quality pellets for resale, choosing the ideal granulator can be a critical decision [...]

Polyvinyl chloride (PVC), identified by plastic code #3, is one of the most problematic contaminants in the PET recycling industry. Even at minimal concentrations, PVC can cause significant issues during the processing of post-consumer PET resins into new products. For instance: PVC contamination can have negative effects at concentrations as low as 50 parts per million (ppm). This 50 […]

Hello and welcome! If you are involved in the recycling industry, production, or seeking sustainable investment opportunities, you are likely already familiar with the enormous challenge and valuable opportunities that plastic waste—and particularly PET bottles—present. Today, we focus on an essential piece of equipment that is central to the conversion of plastic waste into valuable resources. […]

Polyvinyl chloride (PVC) is one of the most versatile plastics, used in a wide range of products from rigid construction pipes to flexible floor coverings and medical hoses. This versatility stems from the ability to formulate the material in countless ways. For companies involved in PVC recycling or processes requiring fine powders, however, this variability can be a double-edged sword [...]

In plastic processing and recycling, selecting the right plastic granulator is crucial. Whether you are processing production waste, defective parts, or post-consumer waste, the efficiency of your granulator has a direct impact on productivity, the quality of the recycled material, and your ultimate profitability. A wrong choice can lead to costly downtime, poor quality output, and lower […]

Our robust plastic granulators, also known as plastic crushers, are an essential component within the plastic recycling industry. Specifically designed for maximum durability, these granulators quickly and efficiently shred various plastic materials into uniform flakes or reusable granulates, significantly improving your recycling process. These versatile machines are among our most sold equipment and are frequently integrated into complete […]

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics