Learn everything about plastic granulators: operation, applications, maintenance, and benefits. The perfect guide for sustainable and efficient plastic processing.

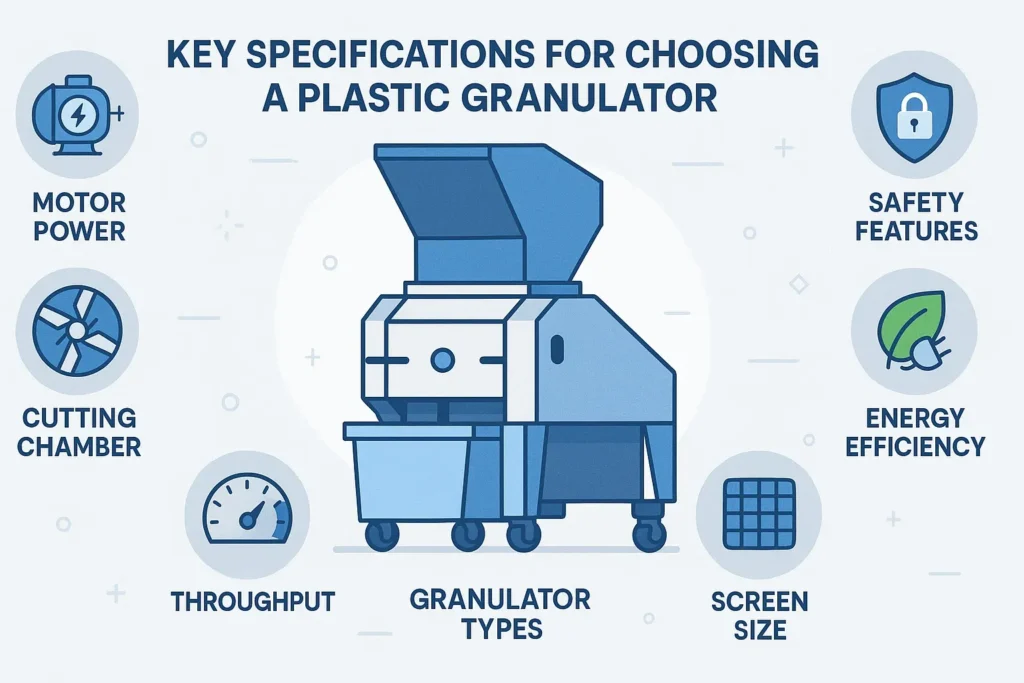

A plastic PET granulator is an essential machine for the efficient recycling of PET waste such as bottles and packaging. This machine reduces waste to uniform granulate (raw material), which serves as a feedstock for new products. This guide covers the operation, the main benefits such as cost savings and sustainability, and the crucial features professionals should consider when purchasing, such as knife quality and the option for wet granulation.

Granulator for Recycling WPC Material (Wood-Plastic Composite)

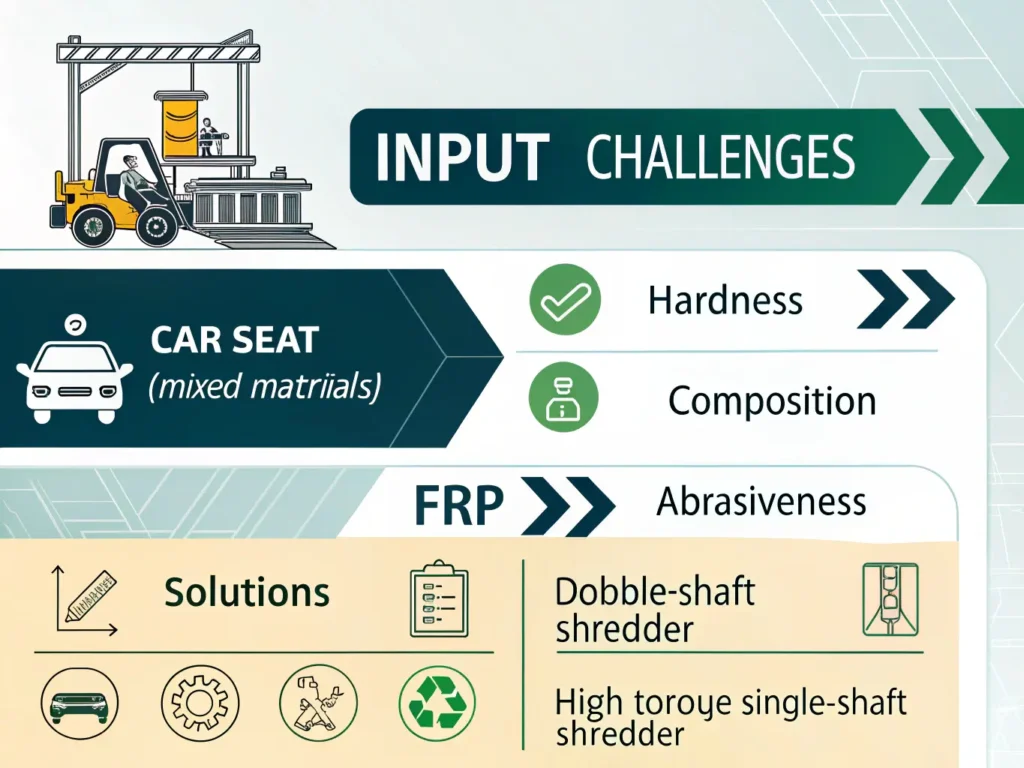

Granulator for Recycling WPC Material (Wood-Plastic Composite) Granulators for Hard Plastics

Granulators for Hard Plastics