Choosing the Right Screen Size for Your Plastic Granulator

Selecting the correct mesh size for the screen of your Plastic granulator is crucial for optimizing granulation processes, ensuring efficiency, and maximizing output quality. This comprehensive guide is specifically developed for industrial equipment buyers, engineers, and technical staff, and provides clear, directly applicable insights.

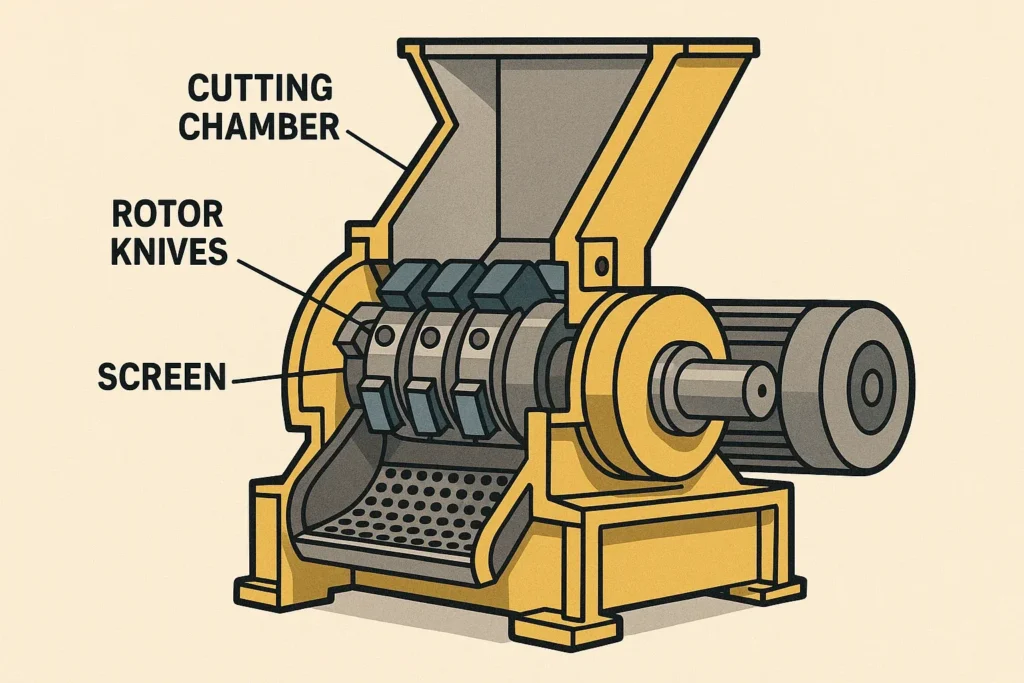

Understanding the Role of Plastic Granulator Screens

A screen in a plastic granulator plays a critical role by controlling the particle size of the feed material. Screens with correctly sized openings ensure consistent particle dimensions, which affects subsequent processing steps, including injection molding, extrusion, and recycling.

Factors Influencing the Selection of Screen Size

When choosing the right screen size, several critical considerations come into play:

- Material Type: Different plastics, such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), require different screen sizes based on their processing properties.

- Desired Particle Size: The required particle size has a significant impact on the screen size. Smaller screen openings produce finer particles, while larger openings result in coarser granulate.

- Throughput Capacity: A higher throughput capacity may require larger screen openings, finding a balance between output and quality.

Impact of Screen Size on Equipment Performance

It is crucial to understand how the screen size affects the performance of the granulator:

| Screen Opening Diameter | Particle Size | Throughput Efficiency | Energy Consumption |

|---|---|---|---|

| Small | Fine | Lower | Higher |

| Medium | Average | Optimal | Average |

| Large | Coarse | Higher | Lower |

- Small Screens: Produce finer particles, beneficial for precision injection molding, but can increase energy consumption and reduce throughput.

- Medium Screens: Offer a balance between quality and efficiency, suitable for most general applications.

- Large Screens: Provide higher throughput with lower energy consumption, suitable for less precise bulk processing.

Step-by-Step Guide for Selecting the Screen Size

- Define Your Requirements:

Clearly define your final product specifications, including particle size and application. - Analyze Material Properties:

Evaluate the type of plastic, hardness, and elasticity. Brittle plastics can efficiently utilize smaller screens, while tougher materials may require larger openings. - Calculate Production Volume:

Align the screen size with production goals, considering the ratio between throughput and quality. - Test and Optimize:

Conduct tests with different screens to empirically determine the optimal balance between particle size, throughput, and energy efficiency.

Tips for Optimal Maintenance of Granulator Screens

- Regularly inspect and clean screens to maintain peak operational efficiency.

- Immediately replace screens showing signs of wear or damage to prevent downtime and reduced productivity.

Conclusion: Achieving Optimal Performance

The choice of the correct mesh size for the plastic granulator screen directly affects productivity, efficiency, and product quality. By carefully evaluating your requirements, understanding material properties, and systematically testing screen sizes, you can ensure that your granulation processes deliver optimal performance. Use this guide as a basis for informed, strategic decisions about equipment, such as the Standard plastic granulators, for sustainable operational success.