Granulators for Hard Plastics

Rumtoo Machine offers powerful, quiet, and easy-to-maintain solutions for the recycling of rigid plastics. Discover how our machines can improve your workflow.

Request a QuoteRumtoo Machine offers powerful, quiet, and easy-to-maintain solutions for the recycling of rigid plastics. Discover how our machines can improve your workflow.

Request a QuoteThese granulators are versatile for production and recycling. By internal grinding, you reduce waste and logistics costs, improve OEE, and increase the value of by-products.

Grind waste streams directly back into the line. Less virgin material needed and a quick ROI.

Grind snip remnants and pipe ends. The ground material is ideal for regranulation or direct reuse.

Layer-by-layer cutting produces homogeneous ground material (12–40 mm) with high output.

Significant volume reduction and lower logistics costs. Robust machine for continuous operation.

Fine and clean feedstock for closed-loop applications and higher yield.

Second step after shredding for higher line capacity and uniform product.

Access to the cutting chamber and filter screen within seconds – faster cleaning, less downtime.

Adjustable knives ensure precise cutting and easy resharpening when needed.

Integrated sound insulation makes indoor use comfortable and safe for personnel.

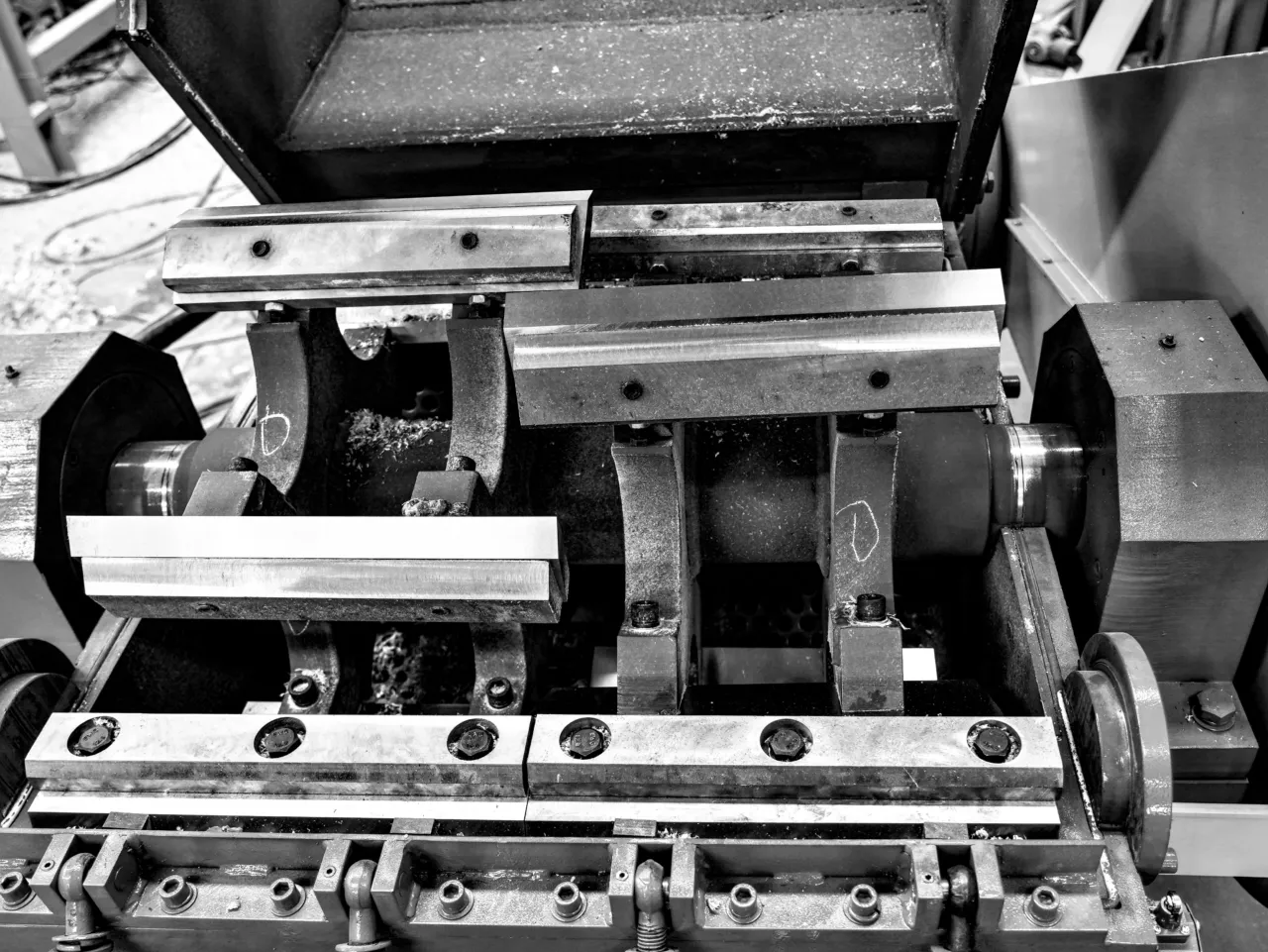

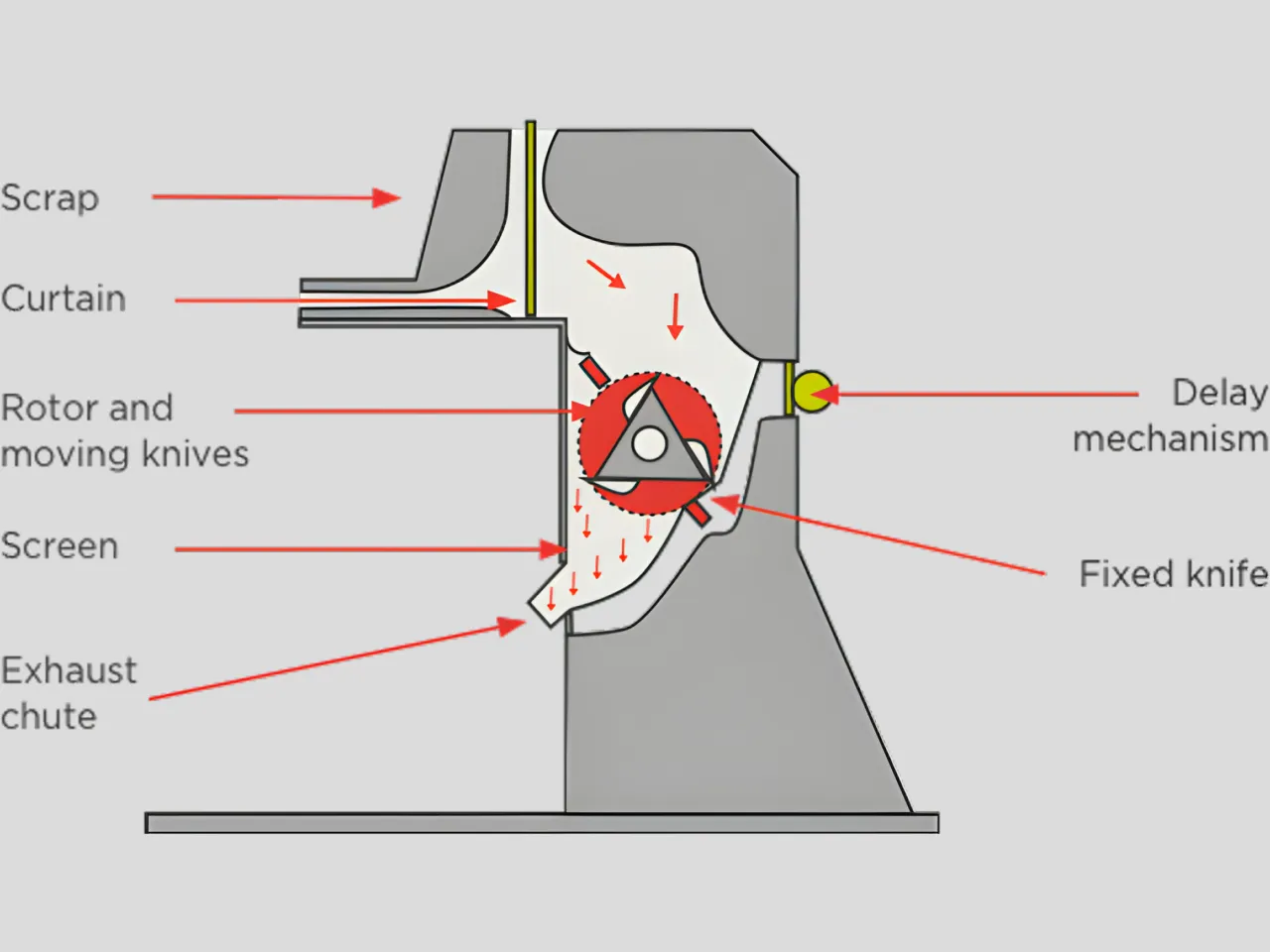

Our granulators are designed for shredding hard plastics down to 2 cm thick. Thanks to the stepped system of the blades and the wide rotor, the material is cut layer by layer until it is small enough to pass through the sieve.

Standard models reach up to 300 kg/hour. For larger volumes, we offer XL models up to 1200 kg/hour.

| Model | Unit | ERMRG600 | ERMRG800 | ERMRG1000 | ERMRG1200 |

|---|---|---|---|---|---|

| Motor Power | kW | 22/30 | 37/45 | 55/75 | 90/110 |

| Number of Moving Blades | pcs | 2×3 | 2×3/2×5 | 2×3/2×5 | 2×3/2×5 |

| Number of Fixed Blades | pcs | 2×2 | 2×2 | 2×2 | 2×2 |

| Crushing Rotary Dimension | mm | Φ450×600 | Φ580×800 | Φ580×1000 | Φ680×1200 |

| Feeding Mouth Dimensions | mm | 600×700 | 600×1000 | 600×1200 | 600×1200 |

| Screen Aperture | mm | Φ12–Φ100 | Φ12–Φ100 | Φ12–Φ100 | Φ12–Φ100 |

| Drive Mechanism | – | Electric | Electric | Electric | Electric |

| Drive Unit Power | kW | 1.1 | 1.1 | 1.1 | 1.1 |

| Dimensions | mm | 2160×1620×2900 | 2230×1820×2900 | 2230×2020×2900 | 2230×2020×2900 |

* CE-certified. Larger models available upon request.

All Rumtoo Machine machines come with a 1-year limited warranty – your peace of mind guaranteed.

Would you like more information, lead time, or pricing? Fill out the form below and our team will contact you promptly.