INDUSTRIAL RECYCLING SOLUTION

Textile and Carpet Waste Simple Assen Shredder

An efficient industrial solution designed to process and recycle textile waste generated during production. Our shredder increases material density through precision cutting and shearing, optimizing waste management, storage, and recycling capabilities.

Key Features

The mainshaft of the shredder is manufactured as a solid, integrated component with CNC processing, ensuring no weld points. This improves durability and structural integrity under heavy loads.

Equipped with an H-series reducer, the shredder operates at a lower speed and higher torque. This feature enhances cutting efficiency while maintaining operational stability.

The blades are made of high-quality D2 alloy steel that has been heat-treated. This makes them highly effective in cutting various materials, including heavy plastics, textiles, and light metals.

The reducer and main shaft are directly connected to minimize energy loss. Additionally, the reducer features built-in shock absorbers that reduce buffer forces during operation, thereby extending the lifespan of the machine.

The shredder utilizes a PLC control system with multiple safety features: Overload protection, automatic reverse function, and forward operation for continuous shredding.

The machine is equipped with a hydraulic system to drive the material feeding carriage. This ensures a smooth, consistent feed with consistent pressure, which improves the precision of the shredding and reduces manual labor.

Technical Specifications

The specifications of the shredder emphasize its suitability for medium-sized applications, ensuring consistent and reliable performance:

Dimensions & Capacity

- Effective Feed Diameter: 300 – 420 mm

- Shredder Chamber Dimensions: 600 mm – 1450 mm

- Production Output: 300–1500 kg/h

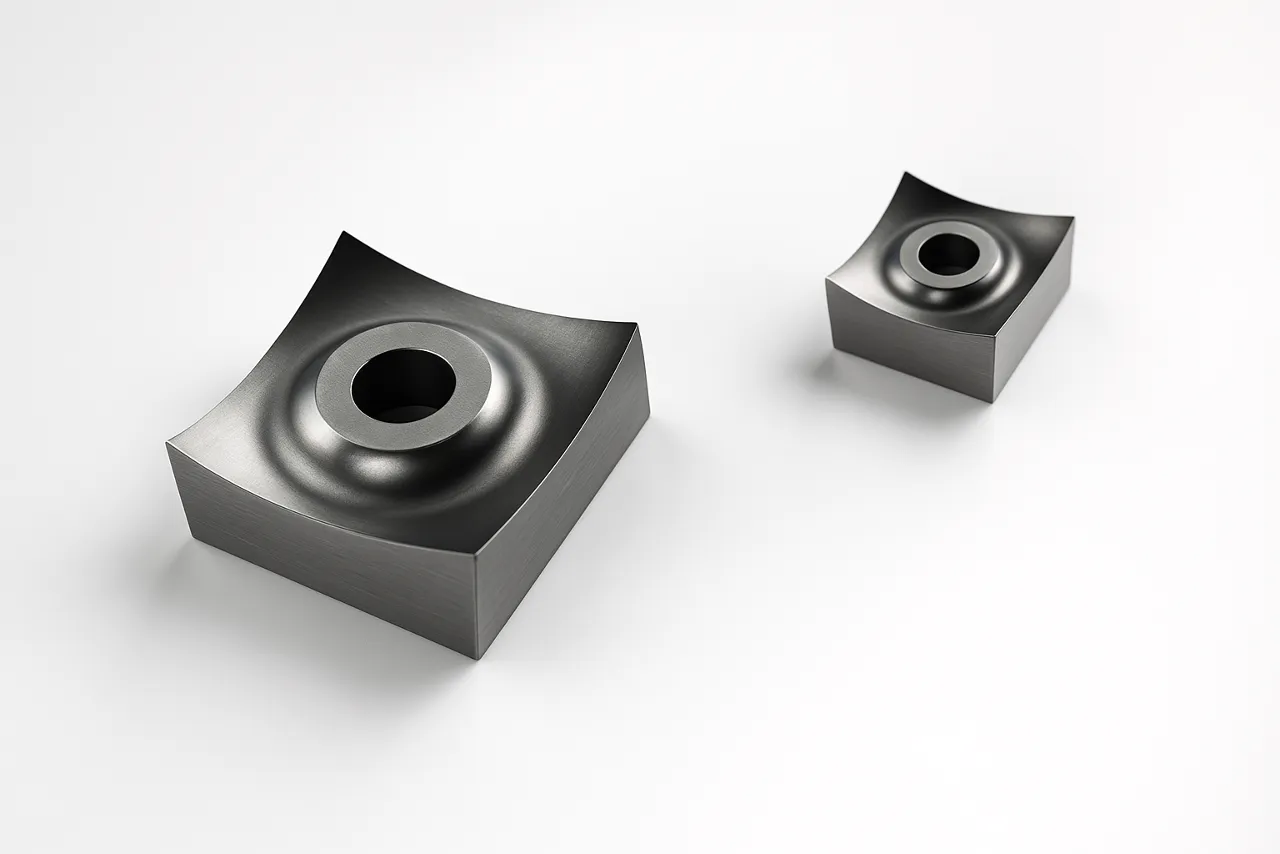

Mes Specifications

- Size (mm): 40×40, 50×50, 60×60

- Material: SKD-11, H13

- Number of Fixed Blades: 4

- Number of Rotating Blades: 30 – 68

Drive and Control System

- Motor Power: 30 – 90 kW

- Output Speed of the Reducer: 72 RPM

- Type of Connection: Direct coupling

- Main shaft: Solid, CNC machined from 45-degree steel

Control Components

- PLC System: Delta

- Electrical Components: Siemens contactors and overload protection

- Buttons: Schneider

- Hydraulic Power: 3 – 6 kW

- Cooling Method: Air cooling

Key Benefits

Improved Sustainability

The solid, integrated design of the shaft and the use of high-quality materials for the blades and walls ensure superior resistance to wear.

Improved Efficiency

With a production capacity of 200–300 kg/h, the shredder processes waste quickly, allowing facilities to streamline their recycling operations.

Operator Safety

Automatic overload protection and reversing systems protect both the equipment and the operator from unexpected issues.

Energy-Efficient Design

The direct drive connection of the machine reduces energy loss, making it cost-effective for long-term operation.

Applications

Textile Industry

Cut waste materials, remnants, and threads for efficient removal and recycling.

Plastic Recycling

Shred films, bottles, and other plastic items for further processing.

Industrial Waste Management

Processing of light metals and other mixed materials for improved removal.

Why Choose This Shredder?

This shredder is specifically designed to meet heavy operational demands with precision and efficiency. The combination of a robust construction, advanced control systems, and thoughtful design features makes it an essential tool for companies looking to reduce waste and enhance their recycling efforts. Investing in this machine not only increases operational productivity but also supports sustainable waste management practices.

What Our Customers Say

“The shredder operates reliably and has significantly increased our processing capacity. Maintenance is simple and the performance is stable.”

“The installation and startup process went smoothly. The machine is energy-efficient and meets our requirements exactly.”

“Excellent service and clear communication. We have seen a direct improvement in throughput and material density.”

Frequently Asked Questions (FAQ)

What materials can the shredder process?

What is the lead time?

Is there a warranty on the machine?

Do you assist with installation and training?

Transform Your Waste Recycling Today

Join innovative facilities that process textile and carpet waste profitably with our single-shaft shredding technology.

✓ QUALITY GUARANTEED: All our recycling machines come with a comprehensive limited warranty of one year.

Ready to optimize your operation? Contact us for customized pricing and lead time information.

Request Information

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics