Conventional shredders often have difficulty gripping thick, large pipes. This system combines a wide horizontal feed trough, high torque, and intelligent load regulation, so that the machine continuously produces with lower risks for operators and lower downtime costs.

Main technical parameters

Only the most important data

Main parameters

| Main Motor Power |

75 kW |

| Diameter of cutting disc |

1600 mm |

| Speed of cutting disc |

600 rpm |

| Diameter of main shaft |

200 mm |

| Material of blades |

D2 |

| Aantal roterende messen |

6 pieces |

| Feed opening |

450 x 450 mm |

| Capacity |

800-1200 kg/h |

| Motor power of feed conveyor |

2.2 kW |

| Belt width of feed conveyor |

500 mm |

Horizontal feeding without pre-processing

The wide feed system makes it possible to load long and heavy pipe sections directly with forklift or crane. This eliminates manual pre-cutting, which increases safety and significantly shortens the processing time per batch.

Hydraulic pusher with PLC control

The hydraulic ram feeds the material continuously under controlled pressure towards the rotor. The PLC automatically adjusts the feeding speed based on motor load, thereby drastically reducing blockages, peak currents, and downtime.

High torque and wear-resistant cutting set

The low-speed rotor with high torque efficiently cuts thick pipe walls into homogeneous chips. Adjustable counter knives and replaceable screens ensure a constant output quality for downstream processes such as washing and extrusion.

Process flow

From whole pipe input to uniform output for further processing

1. Loading

Complete pipes or long sections are horizontally fed with a forklift or crane.

2. Controlled feeding

The hydraulic ram feeds the material automatically and adjusts the force to the work load.

3. Reduction

The rotor and counter knives cut thick pipe walls into homogeneous chips with a stable energy profile.

4. Throughput

Material passes through the screen and goes directly to washing, further reduction, or extrusion.

Performance Comparison

Why this design performs better with large diameter pipes

Conventional shredder

- Often requires preliminary sawing work

- Manual or gravity feeding

- Susceptible to clogging

- Irregular output fraction

This machine

- Direct input of whole pipes

- PLC-controlled hydraulic ram

- Load regulation with fewer blockages

- Consistent chips for line integration

Capacity and particle size are dependent on material, pipe wall thickness, and selected configuration.

Frequently Asked Questions

What is the maximum pipe diameter that this machine can handle?

Standard models process pipes up to Ø1200 mm. For larger diameters, we offer customized solutions up to Ø3500 mm, depending on material and configuration.

Can I set the output size?

Yes. The output is determined by the selected sieve. Typical fractions range between 40 and 120 mm, tuned to your washing or extrusion line.

Is the machine also suitable for PVC pipes?

PVC can be processed, but for structural high PVC capacity, we recommend a specific PVC granulator or a customized line setup.

How is clogging in the hopper prevented?

The PLC-controlled hydraulic ram maintains constant pressure on the material and dynamically regulates the feeding speed based on rotor load.

Can this system be supplied as a complete recycling line?

Yes. We provide complete solutions including conveyer belts, crushing, washing, drying, and pelletizing.

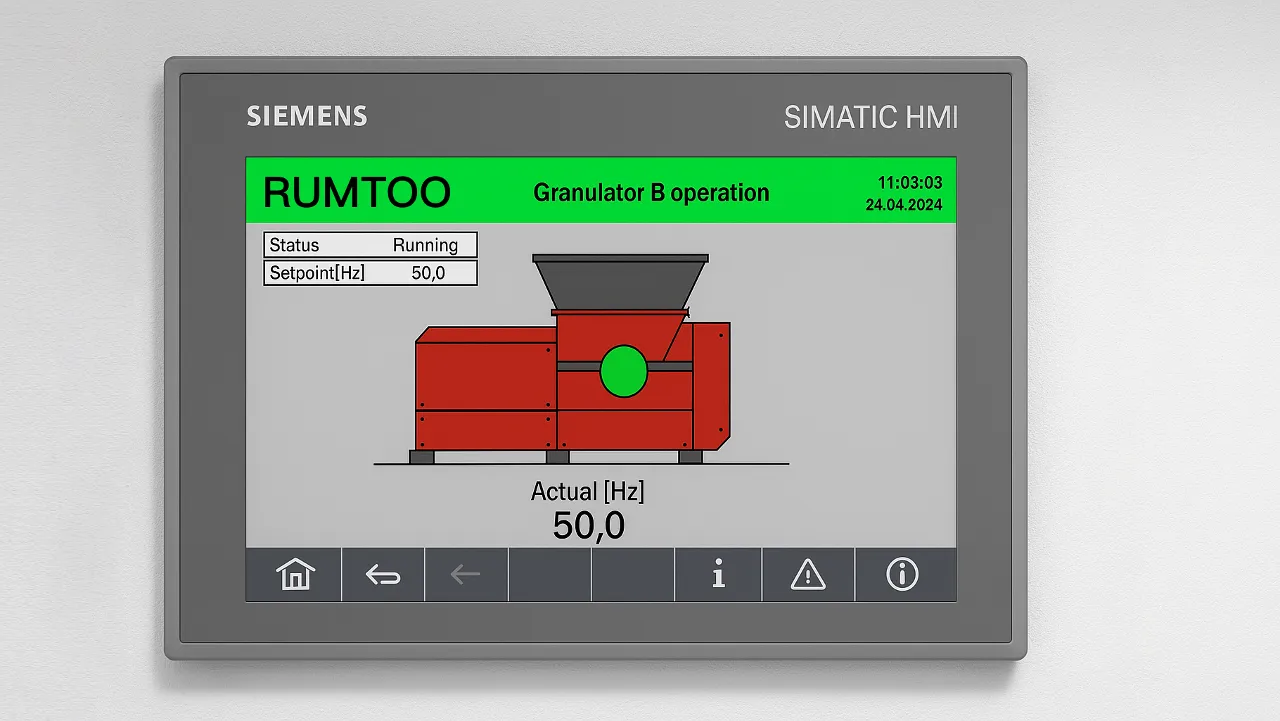

uPVC Profile & Pipe Granulator

uPVC Profile & Pipe Granulator Granulators for Hard Plastics

Granulators for Hard Plastics