Plastic granulators are truly indispensable machines within the plastic recycling ecosystem. They play a critical role in transforming various forms of plastic waste – from bottles and containers to larger industrial remnants – into valuable, reusable materials known as “regrind” or “flakes.” These processed materials can then be reintroduced into the production process, significantly reducing the need for new (virgin) plastics and contributing to a more sustainable future. This article provides an extensive guide to the technology of Plastic Granulators, covering their operating principles, different types, the main factors affecting their granulation speed, specifications for wet granulation, and essential advice on proper use and maintenance. Our aim is to give you a clear understanding of these vital machines.

How Plastic Granulators Work

In essence, they operate according to a simple yet remarkably effective principle. Imagine a set of sharp cutting blades, securely mounted on a high-speed rotating rotor, which rotates rapidly within a robust cutting chamber. This chamber also houses stationary blades. When plastic waste is fed into the granulator (usually through a hopper), the dynamic interaction between the rotating and stationary blades ensures that the plastic is efficiently shredded, chopped, and cut into progressively smaller pieces. At the base of the cutting chamber is a sieve with precisely measured openings. Once the plastic particles are sufficiently reduced to pass through the sieve openings, they are ejected as uniform regrind or flakes, ready for the next stage of recycling or reprocessing. Larger pieces remain in the chamber and are further reduced until they meet the size requirements. Plastic Granulators Types of Plastic Granulators.

Although the fundamental cutting concept is consistent across most models

Hoewel het fundamentele snijconcept consistent is bij de meeste modellen Plastic Granulators, There are various designs developed to meet specific materials, throughput capacities, and operational conditions. The three main types you will often encounter are:

- Double-Blade Cut (or Double-Angle Cut): This advanced design features rotor and stator blades that run parallel but are slightly tilted, creating a true scissor-like movement. This precise configuration ensures a consistent cutting gap across the entire length of the blades. The benefits are numerous: reduced heat generation during operation, minimal power consumption, cleaner and more uniform cuts with fewer fine particles (dust-like particles), and often lower operational noise.

- Chevron or V-Type Rotor: In this popular design, the rotor blades are arranged in a distinctive “V” or chevron pattern. This intelligent configuration continuously draws the plastic material towards the center of the rotor, even as the blades begin to dull. This makes the V-type rotor particularly effective for efficiently processing thicker or robust plastic components and hollow objects, as it prevents material from riding on the blades.

- Helical Rotor (or Spaced Rotor): With blades arranged in a helical or spaced pattern around a closed or semi-closed rotor, this type is designed for toughness. The spaced cut distributes the cutting force, making it exceptionally robust and very suitable for processing particularly thick, dense plastic components or components with a large cross-section. They are often chosen for applications that require high throughput of difficult-to-process materials.

Factors Affecting the Speed and Efficiency of Plastic Granulators

Several interconnected factors significantly influence the speed, throughput, and overall efficiency with which a plastic granulator operates. Kunststofgranulator Plastic Waste Processing:

- Material Type: The intrinsic properties of the plastic to be processed are of utmost importance. Softer, more flexible plastics such as polyethylene (PE) and polypropylene (PP) are generally easier and faster to cut. Conversely, harder, stiffer technical plastics like Acrylonitrile-Butadiene-Styrene (ABS), Nylon (Polyamide – PA), and Polycarbonate (PC) require more cutting force and can be processed more slowly. Bronze plastics can shatter, creating more fine particles, while elastomeric materials are difficult to grip and cut cleanly.

- Size and Design of Cutting Chamber & Knives: A larger cutting chamber can process a greater volume of plastic at any given time. Similarly, longer knives provide a larger cutting surface. The overall geometry of the chamber and the placement of the knives also play a crucial role in how the material flows and is presented at the cutting edges.

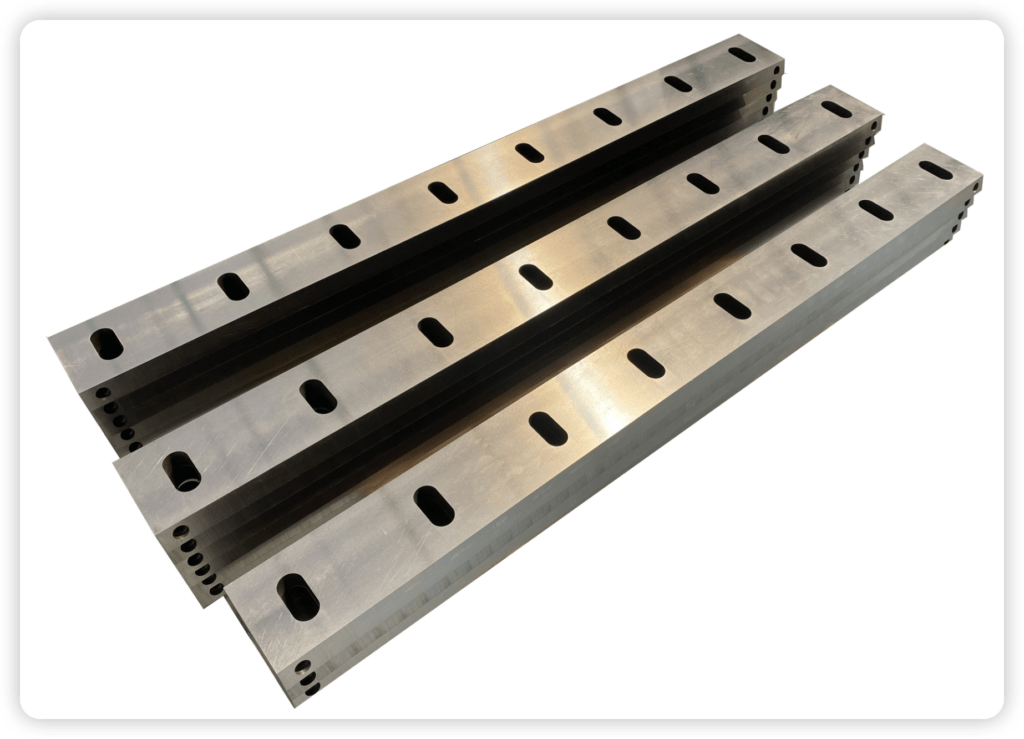

- Quality and Material of the Knives: This cannot be emphasized enough. High-quality knives, typically made from durable, wear-resistant tool steel such as D2 / SKD11, are absolutely essential for efficient, consistent cutting and a longer operational life. Sharp, well-maintained knives require less energy and produce better quality granulate.

- Number of Knives (Rotor and Stator): Generally, a greater number of knives (both on the rotor and the stationary stator knives) translates to more cuts per revolution, leading to faster granulation and potentially finer granulate. However, the optimal number is specific to the design and the material to be processed; too many knives can sometimes lead to clogs with certain materials. Kunststofgranulator en het te verwerken materiaal; te veel messen kunnen soms leiden tot verstoppingen bij bepaalde materialen.

- Motor Power: A more powerful electric motor provides a greater torque, allowing the rotor to spin faster and maintain its speed even under heavy loads. This has a direct impact on the cutting efficiency and the machine's ability to handle tougher materials or higher feed rates.

- Sieve Size (Diameter of the Openings): The size of the openings in the discharge sieve determines the final size of the product. Smaller sieve openings produce finer product, which may be necessary for specific applications, but this also means that the material stays in the cutting chamber longer, reducing the overall throughput. Conversely, larger sieve openings result in faster processing but produce coarser particles.

Wet Plastic Granulators

Wet Plastic Granulators, as the name suggests, integrate a system to introduce water directly into the cutting chamber during operation, usually through strategically placed water sprays or hoses. This seemingly simple addition offers several important advantages:

- Partial Cleaning: The flowing water helps to flush away surface contaminants, such as dirt, sand, and paper labels, from the plastic while it is being reduced in size. This can be particularly useful as a pre-cleaning step in a larger washing line.

- Lubrication and Cooling: Water acts as an effective lubricant between the cutting edges of the blades, reducing friction. This in turn minimizes heat generation within the cutting chamber, which is crucial when processing heat-sensitive plastics that could otherwise melt or degrade.

- Reduced Blade Wear and Dust Suppression: The combination of lubrication and cooling significantly reduces the wear rate of the blades, extends their operational lifespan, and decreases maintenance frequency. Moreover, water helps suppress airborne dust particles, ensuring a cleaner and safer working environment.

Due to these advantages, wet systems are often used in integrated washing lines for plastic oil and hard plastics, where cleaning and large particle reduction occur simultaneously. Plastic Granulators Safe and Efficient Use of Plastic Granulators: Best Practices for Safety and Efficiency.

To ensure the safe, efficient, and long-term operation of your

is essential. Consider these important guidelines: Kunststofgranulator Pre-Use Inspections:

- Always ensure that the cutting chamber is empty before starting the granulator. Turn on the granulator *before* introducing plastic material, allowing it to reach full speed. Zorg er altijd voor dat de snijkamer leeg is voordat u de granulator start. Zet de granulator aan *voordat* u kunststofmateriaal invoert, zodat deze op volle snelheid kan komen.

- Controlled Feeding: Feed material at a constant rate. Avoid overloading or “choking” the feed. For very large or bulky items, a shredder can be a better first step. Avoid feeding in pieces or startup material that exceeds the machine's capacity.

- Caution During Operation: Keep all foreign objects (especially metals and stones) away from the feed. Regularly empty the collection bin for waste material to prevent system blockages.

- System Shutdown: If you are using an exhaust system (blower), stop the granulator *before* you stop the exhaust system. Clean the granulator by allowing it to run empty for a short period before fully shutting it down.

- General Care: Regularly inspect the blades and rotate the screen (if applicable) to extend their lifespan.

Maintenance: Keeping Your Plastic Granulator in Top Condition

Consistent, proactive maintenance is absolutely crucial for extending the operational lifespan of your Kunststofgranulator, ensuring optimal performance and preventing costly, unplanned downtime and repairs. Key maintenance tasks include:

- Machine Care – The Heart of the Equipment: Regularly inspect, grind, and rotate both the rotor and stator blades. Maintain the correct blade gap according to the manufacturer's specifications. Sharp, properly adjusted blades are crucial for efficiency.

- Prevent Damage from Contamination: Keep the cutting chamber free of foreign objects. Consider magnetic separators or pre-sorting if contamination is a recurring issue.

- Health of the Sieve and Chamber: Regularly check and clean the outlet sieve to prevent blockages, which can lead to jamming, overheating, and motor burnout.

- Mechanical Integrity: Adhere to the lubrication schedule for the motor and bearings. Regularly check the tension and condition of the drive belt. Periodically inspect all fasteners for tightness.

By following these guidelines on the principles, types, proper use, and thorough maintenance of Kunststofgranulator-machines carefully understand and apply them, you can effectively utilize this essential technology to optimize your plastic recycling operations, enhance material value, and contribute to a more circular economy.

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics