HEAVY INDUSTRIAL VOLUME REDUCTION

Single-shaft shredder for rubber bands

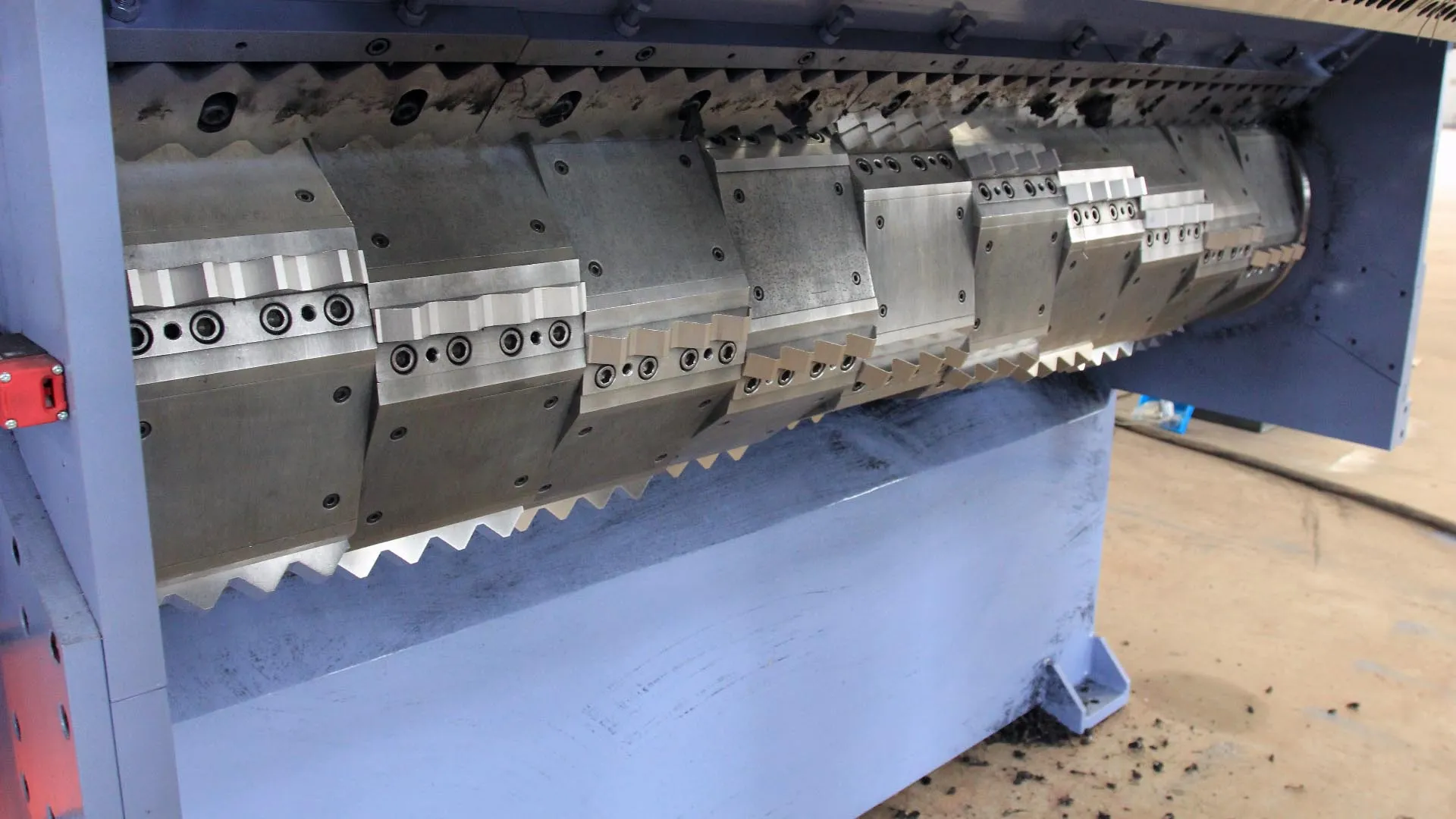

This single-shaft shredder for rubber bands is equipped with a special 3-claw rotor and delivers the aggressive grip and cutting power required to efficiently process tough materials such as rubber bands, TPE, and silicone waste.

Cost-effective solution for rubber bands and tough materials

While double-shaft shredders certainly have their applications, our specialized single-shaft model offers a powerful, low-maintenance, and cost-effective solution for reducing large, elastic materials.

The unique blades with three claws are designed to aggressively grip and pull in bulky, elastic materials, preventing backfiring and achieving a consistent high throughput capacity.

Our specially designed hydraulic drive provides an optimal, constant torque that effortlessly navigates through harsh operating conditions without jamming and outperforms standard electric drives.

Equipped with D2 equivalent tool steel blades for high wear resistance, four times sealed bearings to prevent leakage, and an optimized shock absorption system to protect critical components.

How the Single-Axis Shredder for Rubber Bands Works

A simple, powerful, and effective process for significantly reducing the volume of challenging materials.

Material Feeding

Voluminous rubber or plastic materials are loaded into the hopper of the shredder.

Hydraulic pusher in action

A hydraulically supported pusher automatically presses the material against the rotating shaft of the shredder.

Chopping and cutting

The slowly rotating 3-prong blades grip the material and cut it against fixed blades within the chamber.

Output in sheet size

The material is repeatedly cut until it is small enough to fall through a heavy sieve at the bottom of the machine.

Applications of the rubber band shredder

This shredder excels where standard granulators fall short and is therefore indispensable in specific recycling and processing lines.

Materials

Auto and truck tires, industrial rubber waste, silicone plates and blocks, TPE (thermoplastic elastomers) purgings, EVA (ethyl vinyl acetate) sheets, and large plastic bales and blocks.

Typical Industries

Tyre recycling plants, automotive parts manufacturing, rubber and plastic processing companies, post-industrial waste processing, and shoe and sole production.

Rubber Band Shredder Machine Gallery

Rubber Band Shredder Technical Specifications

| Model | Motor Power | Ass Diameter | RPM | Capacity |

|---|---|---|---|---|

| BS-1000 | 45 kW | ⌀ 450 mm | 55 rpm | 1000 kg/h |

| BS-2000 | 110 kW | ⌀ 500 mm | 45 rpm | 3000 kg/h |

| BS-3000 | 2x 110 kW | ⌀ 550 mm | 40 rpm | 5000 kg/h |

*Capacity is dependent on material type, density, and the mesh size of the screen deck. CE certification available. Larger and heavier models are available upon request.

What Our Customers Say

“The shredder operates reliably and has significantly increased our processing capacity. Maintenance is simple and the performance is very stable.”

“The installation and commissioning went smoothly. The machine is energy-efficient and perfectly meets our requirements.”

“Excellent service and clear communication. We have seen a direct improvement in throughput and material compactness.”

Frequently Asked Questions about the Rubber Band Shredder

Why choose this single-shaft shredder over a double-shaft model?

Why is the 3-claw rotor better for rubber and elastomeric plastics?

What maintenance is generally required?

Request a quote for your rubber band shredder

All our recycling machines are supplied with a limited 1-year warranty. For current prices and lead times, please provide information about your material type and desired capacity.

✓ QUALITY WARRANTY: All our recycling machines are supplied with an extensive 1-year limited warranty.

Request a Quote

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics