INDUSTRIAL CUTTING MACHINES

RTM Series Plastic Granulator

High-capacity cutting machines designed for efficiently reducing pre-sized plastics to a uniform, desired final size.

Granulators, or cutting machines, are generally used as secondary shredders in a recycling facility. The material is already pre-sized and now needs to be granulated to the desired final size. All machines are characterized by a robust steel construction, easy access for maintenance, and high throughput speeds. Common applications include the secondary reduction of films, jerrycans, thin-walled pipes, profiles, bumpers, and injection molding waste.

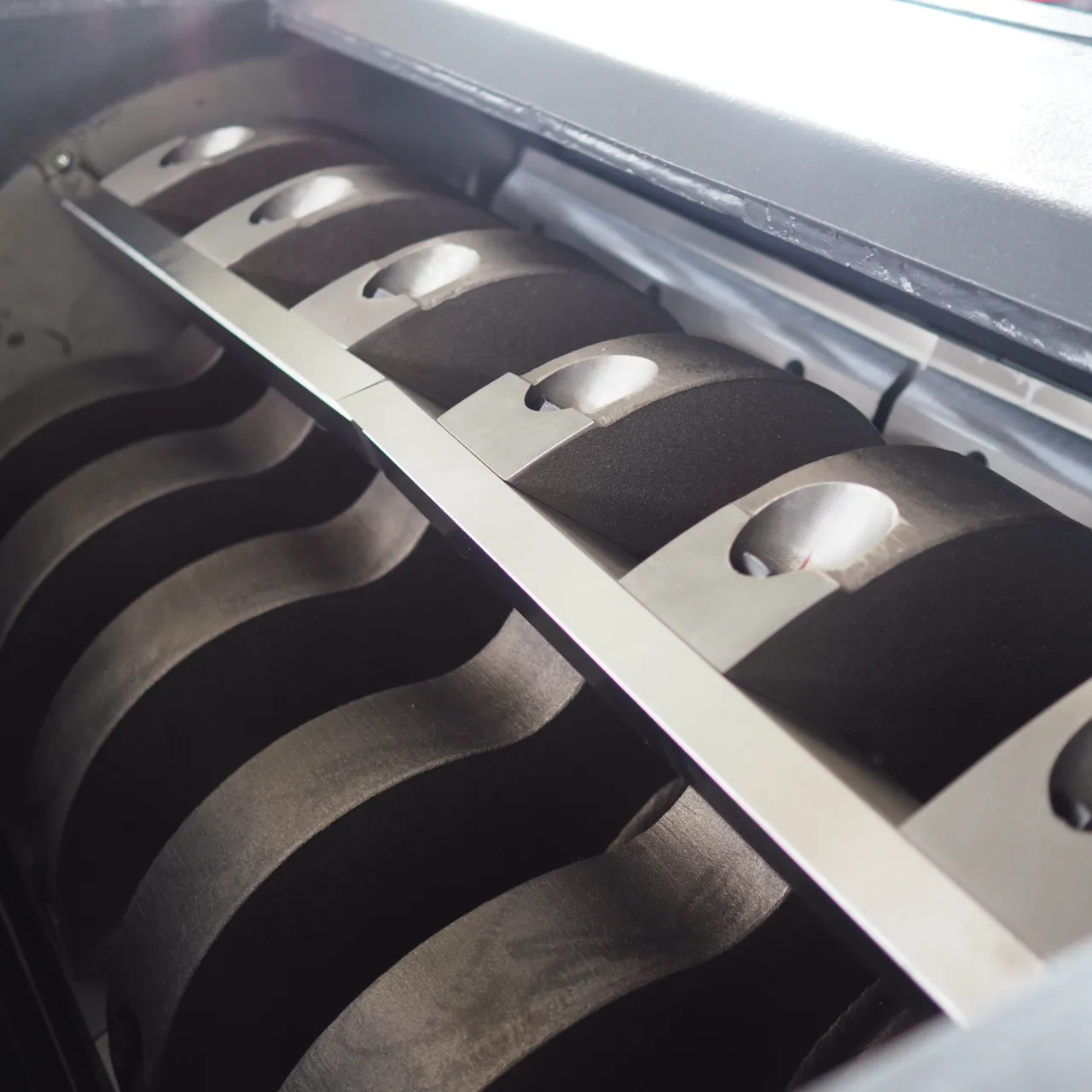

Rugged and Maintenance-Friendly Rotor Bearings

The spherical roller bearings are housed in steel enclosures, separated from the grinding chamber. This prevents dust or material from damaging the bearings. Both bearings are easily lubricated through grease openings, extending their lifespan.

High Cutting Performance with Double-Edge Cutting

The rotating and stationary blades are set at an angle, creating a directed ‘cutting edge’ across the entire working width. This not only ensures a uniform particle size but also has a positive effect on the noise level and energy consumption.

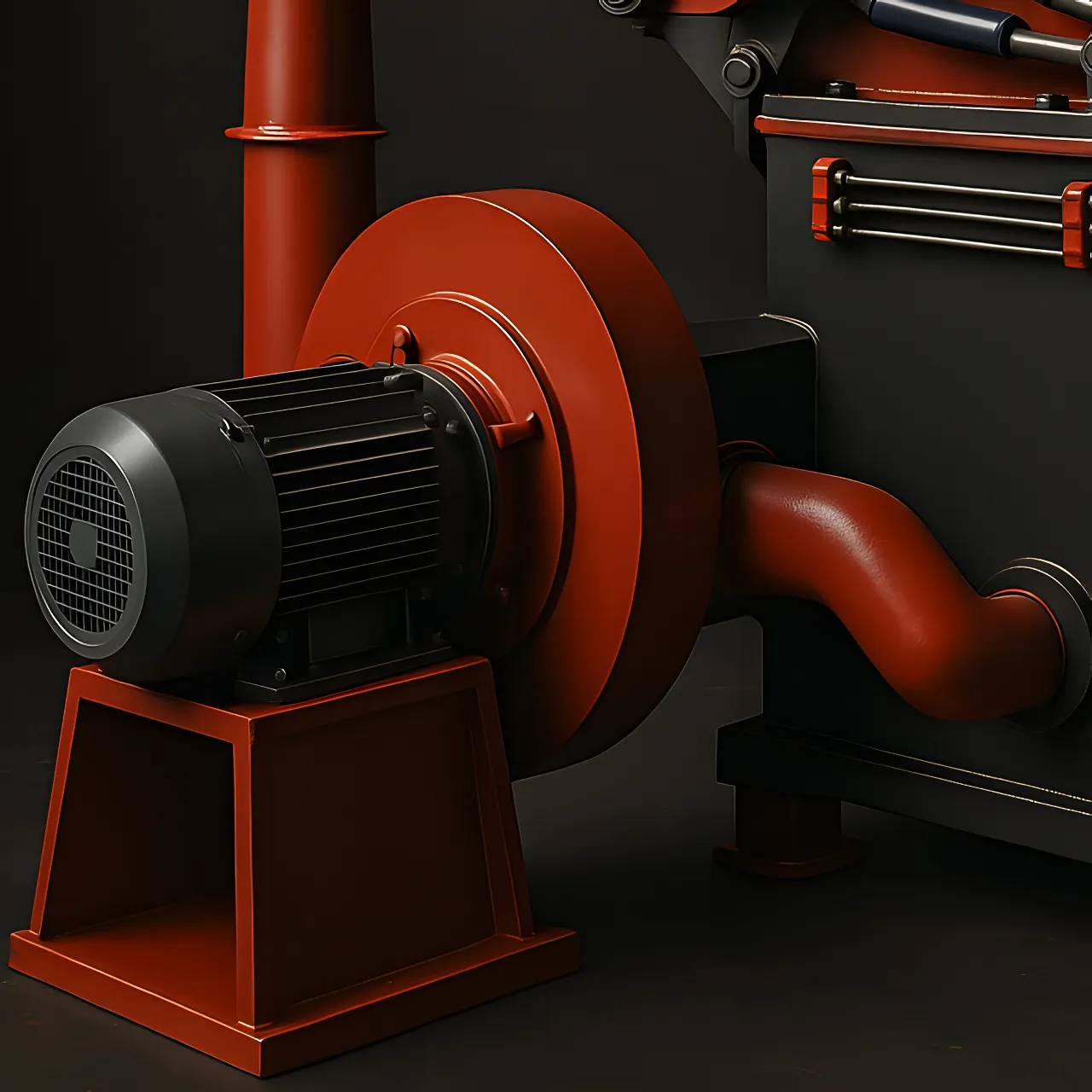

Efficient Material Discharge

The machine is standard equipped with a round exhaust port for efficiently suctioning the granulated material into, for example, big bags. Optionally, a discharge solution with a screw conveyor can also be implemented.

Perfect Cut thanks to Mes-Setting Gauge

To ensure a perfect cutting slot, the blades can be quickly and easily adjusted outside the machine using a setting gauge. Stationary blades can be used on both sides, doubling their lifespan and minimizing downtime.

Compare Our Models

Find the right machine for your application

RTM600

RTM600

|

RTM800

RTM800

|

RTM1000

RTM1000

|

RTM1200

RTM1200

|

|

|---|---|---|---|---|

| Diameter x Length of Rotor (mm) | Φ450×600 | Φ580×800 | Φ580×1000 | Φ680×1200 |

| Size of Feed Opening (mm) | 600×700 | 600×1000 | 600×1200 | 600×1200 |

| Screen Perforation (mm) | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 |

| Motor Power (kW) | 22/30 | 37/45 | 55/75 | 90/110 |

| Number of Rotating Knives (pcs) | 2×3 | 2×3 / 2×5 | 2×3 / 2×5 | 2×3 / 2×5 |

| Number of Stationary Knives (pcs) | 2×2 | 2×2 | 2×2 | 2×2 |

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics