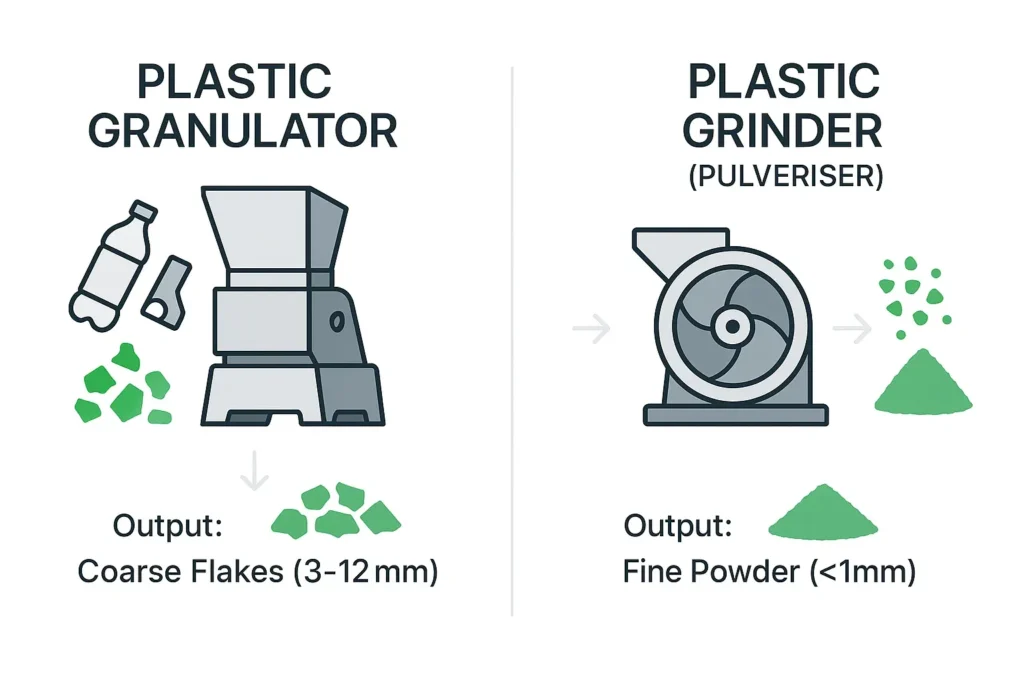

Choosing a Plastic Granulator for Regrind or a Grinder (Pulverizer) for Fine Powder? This guide outlines the crucial differences in operation, output, and application, so you can select the most efficient machine for your process and avoid costly mistakes.

- Plastic Crusher...

-

Newsletter

Sign up for Newsletter

Signup for our newsletter to get notified about sales and new products.

- Plastic Crusher...

Granulator for Recycling WPC Material (Wood-Plastic Composite)

Granulator for Recycling WPC Material (Wood-Plastic Composite) Granulators for Hard Plastics

Granulators for Hard Plastics