In the current industrial landscape, sustainability and efficiency are no longer optional extras, but fundamental pillars of success. The growing pressure to reduce waste mountains, comply with stringent environmental regulations, and manage operational costs is compelling manufacturers and recycling companies to innovate. One of the most impactful technologies in this field is the industrial plastic granulator.

These powerful machines form the backbone of numerous recycling processes and transform vast amounts of plastic waste into valuable, reusable raw material. For companies looking to strengthen their competitive position and play an active role in the circular economy, understanding the benefits of a granulator is essential. In this comprehensive article, we delve deeper into the world of plastic granulation and show how the advanced systems of At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. your operation can be transformed.

What is an Industrial Plastic Granulator Exactly?

Before we discuss the benefits, it is important to understand the core function of the machine. An industrial plastic granulator, also known as a shredder, is a machine designed to grind plastic waste into small, uniform particles known as “regrind” or “flakes.”.

The process is based on a high-speed cutting mechanism. Plastic waste—ranging from production errors, rejected parts, and purification blocks to post-consumer products such as bottles, containers, and films—is fed into a hopper. Inside the cutting chamber, blades rotate at high speed along stationary blades, cutting the plastic with precise shearing action. A perforated screen under the cutting chamber determines the final size of the granulate, which is then discharged for further processing.

The machines of At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. are designed to process a wide range of polymers, including HDPE, LDPE, PET, PP, PVC, ABS, and PS, making them highly versatile for various industrial applications.

The Core Benefits of Plastic Granulators in Your Recycling Process

The implementation of a high-quality plastic granulator delivers a series of strategic benefits that extend beyond waste processing. Let's examine the main benefits in detail.

Significant and Direct Cost Savings

This is often the most compelling reason for companies to invest in a granulator. The cost savings are diverse and directly measurable:

-

Lower Waste Disposal Costs: Disposing of large, unprocessed plastic waste to landfills or external processors is expensive. By granulating this waste internally, you drastically reduce the volume and eliminate or significantly reduce these disposal costs.

-

Creation of a Valuable Raw Material: The granulate you produce is no longer waste; it is a raw material. This regranulate can be reused directly in your own production processes, reducing the need to purchase expensive, new (virgin) plastics. If you do not reuse the material yourself, it can be sold to other manufacturers, generating a new revenue stream.

-

Reduced Transport and Storage Costs: Granulated plastic has a much higher density than unprocessed waste. This means it requires much less storage space and can be transported more efficiently, leading to lower logistics costs.

The energy-efficient motors and the smart design of the granulators from At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. ensure, in addition, that operating costs remain low, further maximizing the return on your investment.

2. Improved Operational Efficiency and Workflow

A granulator streamlines your internal waste management and enhances overall productivity:

-

Automation of Waste Processing: Manually managing plastic scrap is time-consuming and labor-intensive. A granulator automates this process, allowing your staff to focus on core tasks with higher added value.

-

Consistent Quality of Regrind: Modern granulators produce a uniform, high-quality granulate. This consistency is crucial for subsequent processes such as extrusion or injection molding, as it ensures a predictable and stable end product.

-

Integrated Solutions: Granulators can be seamlessly integrated into a complete recycling line, often alongside conveyors, washers, and dryers. This creates a closed-loop system within your factory, where waste is directly converted into reusable material.

3. Increase in Material Value and Market Compliance

Unprocessed, mixed, or bulky plastic waste has a very low, sometimes even negative, market value. Granulation completely reverses this process.

Clean, uniform, and sorted regranulate is a sought-after raw material on the global market. By granulating your waste, you transform a cost into a tradable product. This not only makes your business more efficient but also more resilient against fluctuations in the prices of new raw materials. Moreover, the ability to offer a certified, recycled raw material strengthens your market position.

4. Proven Sustainability and Environmental Impact

Investing in a plastic granulator is a powerful statement about your company's sustainability ambitions.

-

Contribution to the Circular Economy: Instead of the linear “take-make-dispose” model, granulation facilitates a circular model where materials remain within the economy. This is the essence of the circular economy.

-

Reduction of the CO2 Footprint: Reusing plastic requires significantly less energy than producing new plastic from fossil fuels, resulting in a significantly lower emission of greenhouse gases.

-

Compliance with ESG Goals: Companies are increasingly being evaluated on their performance in terms of Environment, Social, and Governance (ESG). A robust internal recycling program, with a granulator as a core component, is a concrete and measurable way to improve your ESG profile, which is attractive to investors, customers, and talent.

5. Flexibility and Versatility

Not all plastic waste is the same. The strength of a modern granulator lies in its ability to be tailored to specific needs. At At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. we understand that each application is unique. That's why we offer a wide range of configurations:

-

Different Rotor Designs: An open rotor is ideal for large, hollow parts, while a closed rotor is more suitable for hard, thick-walled materials.

-

Adjustable Screen Sizes: The mesh size of the screen determines the final particle size, ensuring it is perfectly matched to your subsequent process.

-

Various Feed and Discharge Systems: From manual feed to fully automated systems with conveyors and extraction installations, the machine can be integrated into any existing setup.

For an overview of the different options, please Standard Plastic Granulators view our which can serve as a basis for a customized solution.

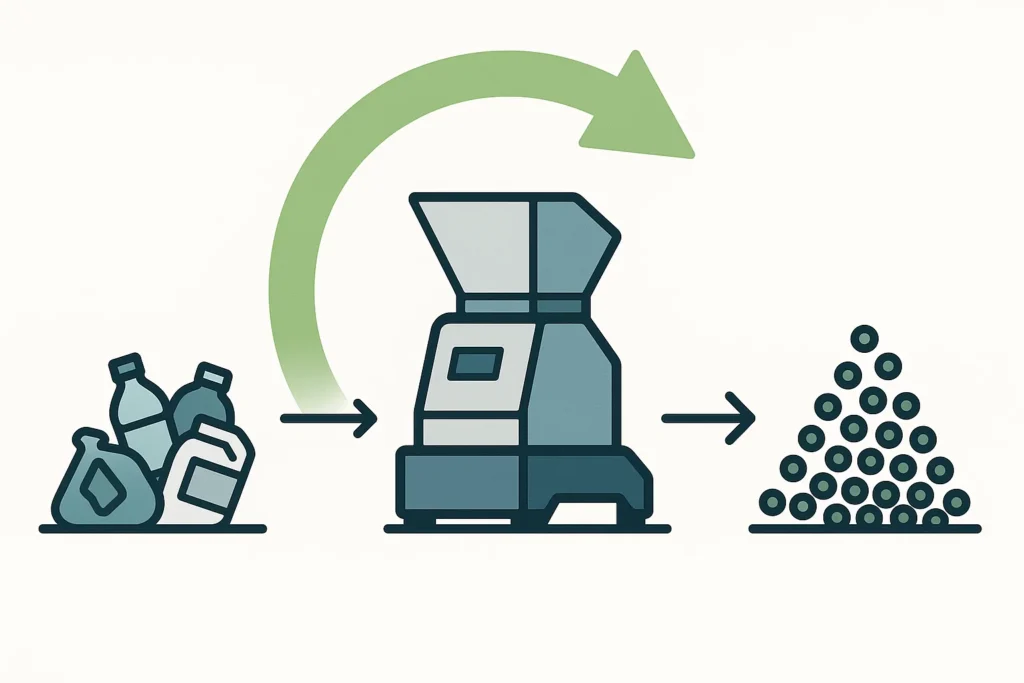

Diagram: The Workflow of a Rumtoo Plastic Granulator

To visualize the process, the following step-by-step description of the operation is provided, which illustrates the workflow diagram below.

(Description in place of a visual diagram)

Granulation Process Workflow

-

Step 1: Feeding

-

Plastic waste (e.g., production waste, bottles, containers) is introduced into the machine through a hopper. This can be done manually or automatically via a conveyor belt for continuous feed.

-

-

Step 2: Cutting Chamber

-

The material enters the cutting chamber. Here, a heavy rotor with high-speed knives mounted on it rotates.

-

These rotating knives move along one or more stationary knives that are fixed to the machine housing.

-

Through the precise, small gap between the knives, the plastic is reduced with an efficient shearing or cutting motion. This prevents melting and dust formation.

-

-

Step 3: Screening

-

Below the cutting chamber, there is a removable, perforated screen.

-

The plastic particles remain in the cutting chamber until they are small enough to fall through the holes in the screen. The size of these holes determines the maximum size of the final product (the regrind).

-

-

Step 4: Discharge

-

The uniform granulate falls through the screen and is collected in a bin beneath the machine.

-

For large-scale operations, the material is often transported directly to a big bag, silo, or the next processing step via a pneumatic extraction system.

-

[End of diagram description]

Choosing the Right Granulator: What to Look Out For?

Choosing the right granulator is a critical decision. To find the perfect match for your company, you should consider the following factors:

-

Type and Shape of Material: Process hard, brittle plastics (such as ABS or PC) or soft, flexible films (LDPE)? Are the parts large and hollow, or small and solid? The type of material determines the required rotor design and motor power.

-

Required Throughput ( kg/h ): How much waste do you produce per hour or per day? Choose a machine with a capacity that meets your current and future needs, without constantly running at maximum load.

-

Desired Pellet Size: What is the ideal size of the regrind for your application? This determines the screen mesh size you will need.

-

Integration into Existing Lines: How does the granulator fit into your current production line? Consider the available space, the feed height, and the method of discharge.

The team at At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. has the expertise to guide you through this selection process and configure a solution that is perfectly tailored to your specific operational requirements.

FAQ – Frequently Asked Questions

1. What is the difference between a shredder and a granulator?

A shredder is designed for primary, coarse reduction of very large or heavy materials (e.g., tires, complete bales of plastic). It operates at low speed with high torque and produces irregular pieces. A granulator is a secondary reduction machine that operates at high speed to grind material into small, uniform granules (regrind). Often, a shredder is placed before a granulator in a recycling line.

2. How much maintenance does an industrial granulator require?

Regular maintenance is crucial for optimal performance. The main tasks include checking, sharpening, and/or replacing the blades, cleaning the cutting chamber, and inspecting the screen for wear. The granulators from At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. are designed for easy access to the cutting chamber, allowing maintenance to be performed quickly and efficiently.

3. Can a Rumtoo granulator be customized to my specific waste stream?

Absolutely. Customization is one of our core competencies. We analyze your material, throughput requirements, and operational context to determine the perfect configuration, including the correct rotor, blade set, screen size, and feed/exit systems.

4. What is the average return on investment (ROI) for a plastic granulator?

The ROI varies depending on factors such as the amount of waste processed, the cost of waste disposal, and the market value of the produced regrind. Many of our customers, however, see a payback period of 12 to 24 months, thanks to significant savings on disposal costs and the purchase of new raw materials.

Take the Next Step Towards Efficient and Sustainable Recycling

The implementation of an industrial plastic granulator is more than a purchase; it is a strategic investment in the future of your business. It enables you to reduce costs, increase efficiency, create new revenue streams, and significantly strengthen your sustainability profile.

With the reliable, high-quality, and customized solutions of At its core, a wet grinding and granulating machine (also known as a wet granulator or washing granulator) is a heavy-duty industrial reducer designed to process large quantities of water during the cutting process. It is specifically developed for the plastic recycling sector to process contaminated post-consumer or post-industrial plastics. you can be sure of a partner who speaks your language and understands your challenges. We don't just supply a machine; we provide a complete solution that achieves your recycling goals.

Are you ready to turn your plastic waste into profit?

Contact our team of experts today for a free consultation or request a direct quote. Let's find the perfect granulator for your business together.

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics