Top 10 Specifications to Check Before Ordering Your Plastic Granulator

Are you considering purchasing a new plastic granulator (also known as a mill or shredder) for your company? Whether you aim to enhance your recycling operations or streamline your material processing, it is absolutely crucial to get the technical details right. For industrial buyers, engineers, and technical experts on your team, focusing on the right specifications makes all the difference between a machine that runs smoothly and efficiently and one that causes headaches. Let's delve deeper into the top 10 technical specifications that should be on your checklist before you sign that order. By doing so, you ensure a wise investment! 1. Material Compatibility: Can it handle your 'plastic diet'? Why it's important: This is the starting point. Your granulator must be perfectly matched to the types of plastic you work with daily. From common plastics like PET, HDPE, and PVC to more challenging materials such as ABS or those with additives (such as flame retardants or glass fibers), compatibility is non-negotiable. What to look for:

Clear specification of

Waarom het belangrijk is: Dit is het startpunt. Uw granulator moet perfect zijn afgestemd op de soorten kunststof waarmee u dagelijks werkt. Van veelvoorkomende kunststoffen zoals PET, HDPE en PVC tot lastigere materialen zoals ABS of materialen met additieven (denk aan vlamvertragers of glasvezels), compatibiliteit is niet onderhandelbaar.

Waar u op moet letten:

- Duidelijke vermelding van Compatible Plastic Types.

- Capacity to process materials with specific additives or contaminants For various material densities and shapes.

- (e.g., film, fragments, feedstock/purges). Example: Quick Check Material Compatibility Material Type.

Suitable Granulator Type

| Materiaaltype | Geschikt Granulatortype | Typical Capacity (kg/h) | Maximum Feed Size (mm) |

|---|---|---|---|

| PET Bottles | High Speed | 200 – 1000 | 10 – 15 |

| PVC Profiles | Heavy-Duty / Heavy Duty | 150 – 800 | 12 – 20 |

| ABS Parts | Multi-Purpose / Multifunctional | 250 – 1500 | 5 – 15 |

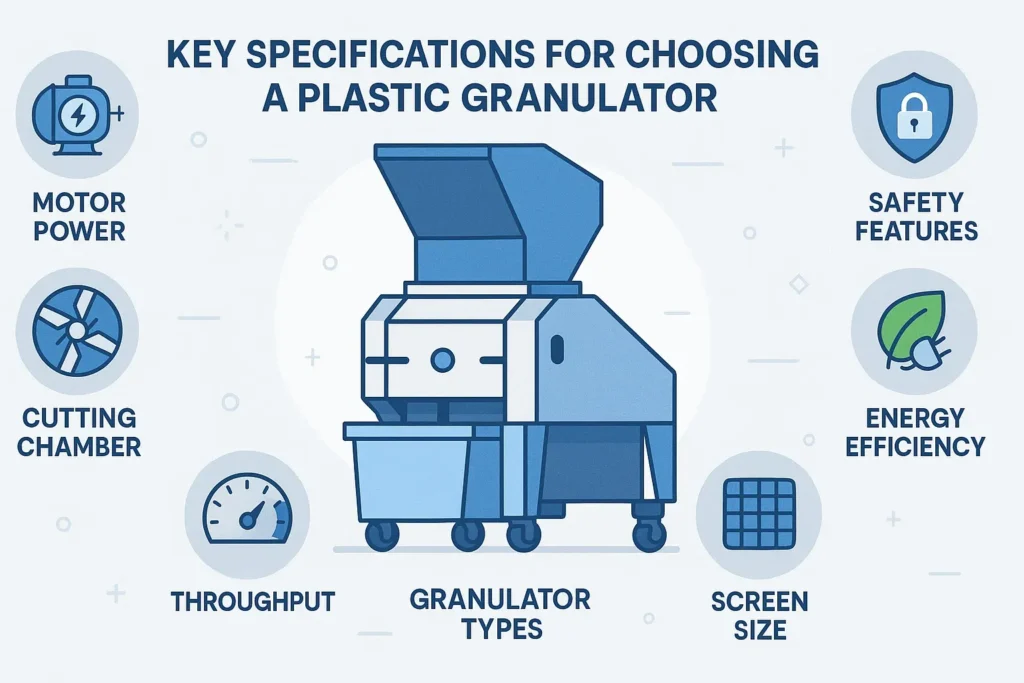

2. Motor Power and Efficiency: The Power Source

Waarom het belangrijk is: The motor is the powerhouse! Its power determines how much material the granulator can process and how easily it can tackle tougher plastics. The right power ensures smooth, efficient operation without getting stuck.

Waar u op moet letten:

- Power Rating (kW or HP) for your heaviest materials and desired throughput. Features that.

- promote efficiency (such as frequency converters / variable speed drives) to manage operational costs. Energy Efficiency Appropriate.

- Duty Cycle classification for your expected operating hours (continuous vs. intermittent). 3. Cutting Mechanism & Blade Configuration: The Heart of the Operation.

How the plastic is cut is crucial. The design of the grinding chamber and the type/configuration of the blades directly affect the quality of the granulate and the machine's ability to process various shapes and thicknesses.

Waarom het belangrijk is: Hoe de kunststof wordt versneden, is cruciaal. Het ontwerp van de maalkamer en het type/configuratie van de messen beïnvloeden direct de kwaliteit van het granulaat en het vermogen van de machine om verschillende vormen en diktes te verwerken.

Waar u op moet letten:

- Mestype & Configuration: Rotor knives (rotating) vs. Stationary knives (fixed), V-notch (chevron), scissor cut, or intermittent?

- Cutting Geometry: Open vs. closed rotor, number of knives.

- Ease of Knife Adjustment & Replacement.

4. Granule Size and Uniformity: Consistency is Essential

Waarom het belangrijk is: The size and consistency of the produced granulate are crucial for the subsequent process, whether it be extrusion, injection molding, or the sale of the finished product. Uniform granulate blends better and leads to higher-quality end products.

Waar u op moet letten:

- Availability of various Sieve Sizes (Interchangeable seven determine the particle size).

- Achievable Particle Size Range (e.g., 6 mm – 12 mm).

- promote efficiency (such as frequency converters / variable speed drives) to manage operational costs. Uniformity of the Granulate guarantee (minimize fines or long pieces).

5. Throughput Capacity (kg/h): Tailored to Your Pace

Waarom het belangrijk is: How much plastic can the machine process per hour? This should align with your production goals. A machine that is too small can cause bottlenecks, while a machine that is too large can be an unnecessary expense.

Waar u op moet letten:

- Realistic Maximum Throughput Capacity (kg/h) for your primary materials.

- Acceptable Material Input Size & Shape To Achieve Throughput.

Example: Instant Throughput Measurement

| Granulator Class | Typical Throughput (kg/h) | Processed Input Size Up to (mm) | Common Materials |

|---|---|---|---|

| Standard Configuration | 500 – 1000 | ~ 5 – 20 | PET, HDPE, PP (smaller parts) |

| Heavy Duty / Heavy Duty | 1000 – 2000+ | ~ 10 – 30+ | PVC, ABS, Thick-Walled Parts, Purges |

6. Noise Levels and Vibration: Comfort & Health in the Workplace

Waarom het belangrijk is: Granulators can be noisy! High noise and vibration levels are not only unpleasant; they can pose health risks and may be in violation of occupational health and safety regulations. Quieter, smoother machines contribute to a better working environment and can indicate higher build quality.

Waar u op moet letten:

- Specified Noise Level (dB) – check if this meets the requirements of your location.

- Integrated Vibration Reduction Features (For example, vibration dampers, sound-insulating enclosures).

Ease of Maintenance and Service Friendliness: Keep It Running Smoothly

Waarom het belangrijk is: Downtime is costly. A granulator that is easy to clean, inspect, and maintain (especially easy access to blades and screens) will save you time and money in the long run.

Waar u op moet letten:

- Tool-free or Easy Access to the grinding chamber, screen, and rotor.

- Features that facilitate cleaning, such as tiltable hoppers or foldable screen holders.

- Clear maintenance guidelines from the manufacturer for the Maintenance Schedule.

- Good Availability of Spare Parts (Monitoring, seven, belts).

Quick Maintenance Checklist Points:

- Frequency of blade inspection, rotation, and replacement.

- Screen cleaning and replacement procedures.

- Lubrication points and schedule.

- Tension control of belts.

8. Safety Measures: Protect Your People

Waarom het belangrijk is: These are powerful machines. Robust safety features are essential to protect operators and comply with safety standards (such as CE marking, Arbowet).

Waar u op moet letten:

- Prominent Emergency stop buttons.

- Safety Locks (Interlocks) on access panels and hoppers (prevent operation when open).

- Motor Overload Protection.

- Effective Enclosures around moving parts and the feed opening.

- Option for rotor locking for safe maintenance.

9. Energy Consumption and Cost Efficiency: Smart Energy Use

Waarom het belangrijk is: Energy is not cheap! An energy-efficient granulator has a direct impact on your business results and is better for the environment. Look beyond the purchase price to the long-term operational costs.

Waar u op moet letten:

- High-efficiency motors (e.g., IE3 or IE4 classifications).

- Functions such as Frequency Converters (VSDs) which adjust the power to the load.

- Information about Energy Consumption in Null Load (Idle).

- Smart controls that minimize unnecessary running time.

10. Automation and Control Systems: Operation Optimization

Waarom het belangrijk is: Modern controls can simplify operation, improve consistency, and enable integration into larger automated systems. Smart features reduce manual effort and optimize performance.

Waar u op moet letten:

- User-friendly Control Interface (e.g., PLC with Touchscreen).

- Automation Features: Auto start/stop, load detection, programmable settings.

- Potential for Integration with Upstream/Downstream Equipment (Conveyor belts, feeders, exhaust systems).

- Options for data logging or remote monitoring.

Making the Right Choice for Your Business Operations

Choosing the right plastic granulator comes down to carefully aligning the technical capabilities of the machine with your specific operational needs. By thoroughly reviewing these top 10 specifications – from fundamental material compatibility and motor power to critical aspects such as maintenance accessibility and energy efficiency – you arm yourself to make a smart, informed investment.

Whether your focus is on recycling efficiency or seamless production integration, the right granulator is a cornerstone of success. It boosts productivity, helps manage costs, and ultimately improves the quality of your recycled materials or end products. Take the time to carefully evaluate these points!

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics