PVC PROFILE RECYCLING

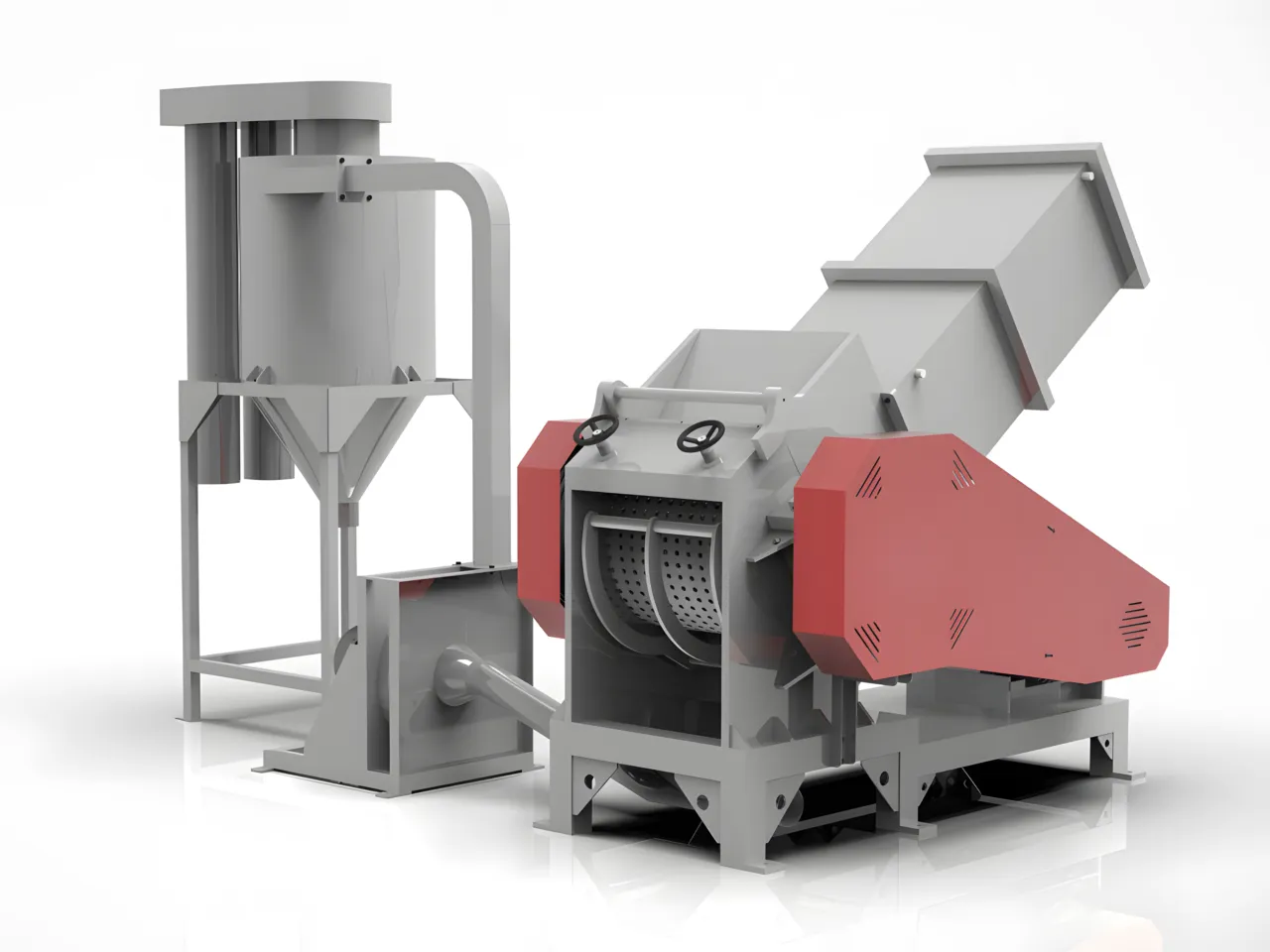

PVC Window & Door Profile Granulator

Designed for rigid PVC (uPVC) profile waste from the window and extrusion industries. Process long profiles, cutoffs, and return materials into uniform flakes with high throughput, low downtime, and reliable dust extraction.

Typical Input: uPVC window/door profiles, frame scrap, PVC profiles, and (optional) PVC pipe cutoffs.

Versatile Applications

Specialized for rigid PVC (uPVC) profiles with stable feeding and consistent reduction. Also suitable for other extrusion and profile streams.

PVC Profiles

Window and Door Profiles (uPVC)

Frame Scrap & Return Profiles

Finish and Construction Profiles

PVC Pipe & Extrusion

PVC Pipe Cutoffs (optional)

Rigid PVC extrusion remnants

Cable channels & conduit systems

Other profiles

ABS Plastic Profiles

PP/PE profiles & extrusions

Acrylic and PC plates

Composites

WPC Materials

Composite profiles

Mixed profile streams

Equipment Details

Advanced Technology for Optimal Performance

Precision Measuring System

Hardened SKD-11 steel blades for maximum durability and cutting efficiency

Intelligent Control System

User-friendly interface with advanced monitoring features

Efficient Feeding Mechanism

Optimized for a consistent material flow and maximum throughput

Integrated Silo & Dust Extraction

High-capacity Storage with Advanced Filtration Technology

Advanced Operating Principles

The granulator is optimized for hard PVC (uPVC) with a stable material flow, controlled reduction, and reliable dust management for a clean and uniform final product.

Convert PVC profile waste into reusable flakes with minimal losses and consistent output quality.

Processing capacity up to 500 kg/h with consistent flake size for subsequent steps such as washing, extrusion, or compounding.

Optimized feed mechanism and PLC monitoring prevent bridging and minimize operator intervention.

Hardened components, safety switches, and (optional) metal protection for profile streams with inserts.

Maximize ROI with low energy consumption and minimal maintenance needs.

Integrated silo and dust extraction improve the working environment and limit dust in the product stream.

Technical perfection

Precision engineering meets innovative design

Processing capacity

350-500 kg/h

Motor power

30-45 kW

Screen Mesh Size

8-10 mm

Number of Blades

10-16 pieces

Opening Method

Electrical

Control System

Advanced PLC

Transform your PVC profile recycling

Optimize the processing of uPVC window and door profile waste with a reliable granulator solution. Request a consultation and receive a customized configuration based on your material and desired output.

✓ QUALITY GUARANTEED: All our recycling machines come with a comprehensive limited warranty of one year.

Request a ConsultationFrequently Asked Questions

What is the capacity for PVC window and door profiles?

Can profiles with steel inserts be processed?

What sieve size should I choose for PVC flakes?

How often should the blades be sharpened or replaced?

Can I integrate washing, transportation, and dust extraction?

What about energy consumption, dust, and safety?

Information Request

Fill out the form below to receive detailed information about our PVC window and door profile granulator, including current prices, customization options, and expected delivery times.

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling

PVC Window & Door Profile Granulator | uPVC Profile Breaker for Recycling Granulators for Hard Plastics

Granulators for Hard Plastics